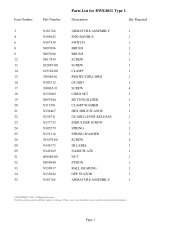

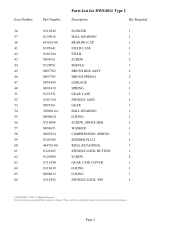

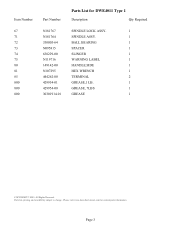

Dewalt DWE4011 Support Question

Find answers below for this question about Dewalt DWE4011.Need a Dewalt DWE4011 manual? We have 2 online manuals for this item!

Question posted by rsmith19953 on September 20th, 2016

Grinding And Cutting Discs, How To Specify?

How, where do we buy discs for this grinder?

Current Answers

Related Dewalt DWE4011 Manual Pages

Similar Questions

My Dewalt Dw317k Will Not Not Cut A Straight Cut

I can not cut a straight cut with my DW317K. If I clamp all pieces to a non-moving surface and secur...

I can not cut a straight cut with my DW317K. If I clamp all pieces to a non-moving surface and secur...

(Posted by Claybyrds 2 years ago)

Can We Buy A New Transfo For A Dewalt Radio Dcr018 ???

(Posted by jeremiemi 3 years ago)

Bolt Size For Dewalt 734 Planner Tool Tray

I need the size of the two bolts used to attach the tool tray to a 734 DeWalt Planner.

I need the size of the two bolts used to attach the tool tray to a 734 DeWalt Planner.

(Posted by luklyd 8 years ago)

Why Won't The Blade Stay In Place While Cutting ?

The blade falls when starting to cut with newly bought jigsaw Dewalt DW331K .Thanks to help.Best reg...

The blade falls when starting to cut with newly bought jigsaw Dewalt DW331K .Thanks to help.Best reg...

(Posted by leo250263 8 years ago)

Is There Anywhere You Can Buy A Dewalt Mt16 Multi Tool Without Having To

buy it together with the MT8 as part of the DeWalt gift box set?

buy it together with the MT8 as part of the DeWalt gift box set?

(Posted by freginold 9 years ago)