Craftsman 28875 Support Question

Find answers below for this question about Craftsman 28875 - Professional 26 HP 52 in. Zero Turn Riding Mower.Need a Craftsman 28875 manual? We have 1 online manual for this item!

Question posted by leeolson on June 21st, 2015

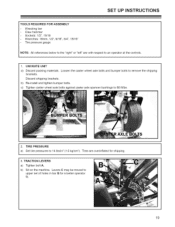

Replacement Bolts For Transaxle

I broke the bolt that attaches the transaxle to the frame. I have replaced it with automotive quality bolts twice but they don't last. Where can I get mfg replacement bolts and nuts for this application?Thank you,Lee Olson

Current Answers

Answer #1: Posted by Odin on June 21st, 2015 11:52 AM

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Related Craftsman 28875 Manual Pages

Similar Questions

Rebuild Carburetor On 1996 Craftsman 19.5 Hp 46' Riding Mower

I'm in need of help rebuilding the carburetor on a 1996 craftsman/ Briggs Stratton riding mower. It'...

I'm in need of help rebuilding the carburetor on a 1996 craftsman/ Briggs Stratton riding mower. It'...

(Posted by gotone4ya59 8 years ago)

How Do I Adjust The Ground Travel On A Craftsman Zero Turn Mower

(Posted by mrBigBe 9 years ago)

Transmission Drive Belt Replacement On Craftsman Zts6000

How Do You Replace A Drive Belt On A Craftsman Zts 6000 Zero Turn Mower

How Do You Replace A Drive Belt On A Craftsman Zts 6000 Zero Turn Mower

(Posted by JAXGEP 9 years ago)

What Size Oil Filter Do It Need For My Zero Turn

(Posted by Anonymous-134248 10 years ago)