Craftsman 21609 Support Question

Find answers below for this question about Craftsman 21609 - 18 in. Scroll Saw.Need a Craftsman 21609 manual? We have 1 online manual for this item!

Question posted by kennymccann on November 6th, 2011

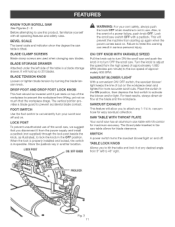

Can The Saw Work Without Foot Switch

The person who posted this question about this Craftsman product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Craftsman 21609 Manual Pages

Similar Questions

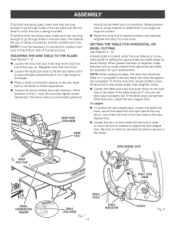

16' Scroll Saw Variable Switch Assembly

I need a 16" Scroll Saw Variable Switch Assembly

I need a 16" Scroll Saw Variable Switch Assembly

(Posted by ldsilva1 9 years ago)

It Is Getting Power. The Light Works But The Saw Will Not Operate.

(Posted by Anonymous-123838 10 years ago)

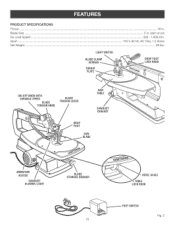

Maximum Cut Depth For 21609 Scroll Saw

I can't find the maximum depth of cut that you can make with the 21609 scroll saw - can you please t...

I can't find the maximum depth of cut that you can make with the 21609 scroll saw - can you please t...

(Posted by brian78088 12 years ago)