Craftsman 21194 Support Question

Find answers below for this question about Craftsman 21194 - 7-1/4 in. Sliding Compound Miter Saw.Need a Craftsman 21194 manual? We have 1 online manual for this item!

Question posted by ccc692 on September 13th, 2015

How To Replace A Broken Spring Of 71/4' Craftsman Slide Compound Miter Saw. Mode

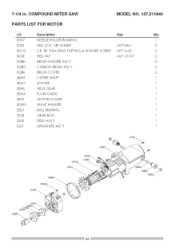

I've a spring broken of 71/4" craftsman slide compound miter saw. Model 137.211940. Please tell me how to replace the broken spring?

Current Answers

Answer #1: Posted by TommyKervz on October 10th, 2015 5:58 AM

It will be simple to perform this task with the help of the service manual/diagram or a professional technician. Please call Craftsman Customer Support 888-331-4569 or click here to fill the request form in requesting either the service manual/ diagram.

Related Craftsman 21194 Manual Pages

Similar Questions

Motor Carbon Brushes

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

(Posted by jriofrio 10 months ago)

Repairing Broken Drive Belt On Craftman Band Saw Model 351.214190

How To Remove The Lower Wheel On Craftman Band saw Model 351.214190. Because The Drive Belt Is broke...

How To Remove The Lower Wheel On Craftman Band saw Model 351.214190. Because The Drive Belt Is broke...

(Posted by AVERBECK 9 years ago)

I Have A Craftsman Compound Saw Model 113.234633c.were Can I Get A Replacement?

(Posted by francesandjack 11 years ago)

Saw Blade Not Centered

i just bought the floor model 12-in Sliding compound miter saw with laser trace M# 137.212390. In...

i just bought the floor model 12-in Sliding compound miter saw with laser trace M# 137.212390. In...

(Posted by randys113 12 years ago)