Brother International BAS-416 Support Question

Find answers below for this question about Brother International BAS-416.Need a Brother International BAS-416 manual? We have 13 online manuals for this item!

Question posted by bettycosentino on September 24th, 2012

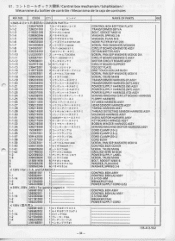

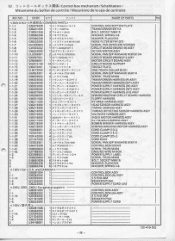

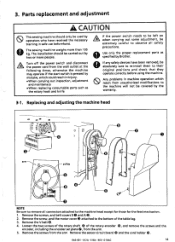

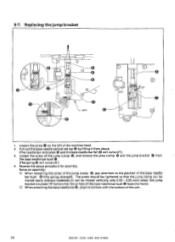

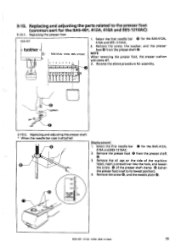

Replacement Parts For Bas 416

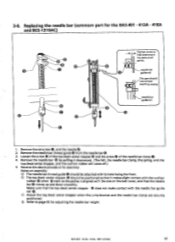

Needle bar cushion replacement parts for bas 416

Current Answers

Related Brother International BAS-416 Manual Pages

Similar Questions

Hi Can Someone Tell Me Why My Screen Has Stopped Working On My Brother Bas-416

(Posted by deansequestrian 2 years ago)

Embroidery Machine Bas 416 Problem

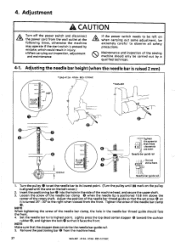

The needles on my brother bas416 industrial embroidery machine will not move up and down. How can I ...

The needles on my brother bas416 industrial embroidery machine will not move up and down. How can I ...

(Posted by cbrooks78 7 years ago)

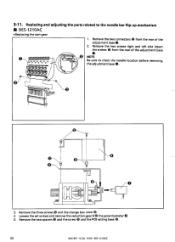

Bas-416 Needle Off

Bas-416 single head nine needle my needle one start off a half inch off when I'm embroidery i change...

Bas-416 single head nine needle my needle one start off a half inch off when I'm embroidery i change...

(Posted by sylviassigns 7 years ago)

Vx1435 Brother Sewing Machine How To Change The Needle

(Posted by Adpad 10 years ago)

Brother Sewing Machine Xr7700 How To Adjust Needle Position For Zipper Foot

(Posted by princje 10 years ago)