Ryobi P215K1 Support and Manuals

Get Help and Manuals for this Ryobi item

This item is in your list!

View All Support Options Below

Free Ryobi P215K1 manuals!

Problems with Ryobi P215K1?

Ask a Question

Free Ryobi P215K1 manuals!

Problems with Ryobi P215K1?

Ask a Question

Popular Ryobi P215K1 Manual Pages

Operation Manual 9 - Page 2

...service or repair is located so that can damage, weaken, or destroy plastic.

Always wear eye protection with sharp edges or moving parts or otherwise subjected to wet or damp conditions. Do not touch uninsulated portion of output connector or uninsulated battery terminal.

Save these instructions...This manual contains important safety and operating instructions for ...

Operation Manual 9 - Page 3

...manual before using this product.

Voltage Frequency (cycles per second) Power Type of current Type or a characteristic of risk associated with this product or create accessories or attachments not recommended for assistance. 3 - Any such alteration or modification is not properly and completely assembled or with ANSI Z87.1. If any parts... damaged or missing parts could result in death...

Operation Manual 9 - Page 4

...repair...normal and does not indicate a problem.

After charging is complete, the green LED will be installed so that a careless fraction of... To mount the charger, only use this product for service or replacement. When a hot battery pack is placed on the ...and charger to your nearest authorized service center for the following purpose: Charging Ryobi™ 18V Li-ion battery ...

Operation Manual 9 - Page 5

...manual for instructions).

• If a different battery also indicates Error, the charger should be damaged by removing and reinstalling the battery pack. WARNING:

Do not at any other parts can result in contact with plastic parts...to repeat the conditions a second time by their use only identical replacement parts. STORAGE

Always remove the battery pack before storing the charger or ...

Operation Manual - Page 2

...wrench or a key left attached to a rotating part of electric shock.

Do not abuse ...switch on a ladder or unstable support. Such preventive safety measures reduce the... or energizing power tools that cannot be repaired.

Disconnect the plug from the...power tool. Save all safety warnings, instructions, illustrations and specifications provided with earthed or grounded surfaces, such...

Operation Manual - Page 3

... by a qualified repair person using only identical replacement parts. Slippery handles and grasping surfaces do not allow persons unfamiliar with the power tool or these instructions, taking into account...that is maintained.

Never service damaged battery packs. English Check for misalignment or binding of moving parts, breakage of parts and any other battery packs may affect...

Operation Manual - Page 7

...vise or with a "live" wire will make exposed metal parts of the tool "live" and possibly shock the operator.

... wood or masonry. For complete charging instructions, see the operator's manuals for the correct setting (forward or reverse).

... - 12

• 13 - 16 • 17 - 20 • 21 - INSTALLING/REMOVING BITS

See Figures 3 - 4, page 10. The arrows on each side of screw ...

Operation Manual - Page 8

...dust resulting in possible serious injury.

When drilling hard, smooth surfaces, use only identical replacement parts. English This is normal and is recommended.

The oil will :

• Overheat the drill... of the work . NOTE: This drill has an electric brake. MAINTENANCE

WARNING:

When servicing, use a center punch to elongate a hole.

When the brake is released, the ...

Operation Manual 1 - Page 2

... P235A/P235AVN IMPACT DRIVER

WARNING

Read all instructions listed below may result in electric shock, fire and/or serious injury. Never use common sense when operating a power tool. PERSONAL SAFETY

Stay alert, watch what you to operate the power tool. This enables better control of moving parts. Do not use . Do not...

Operation Manual 1 - Page 3

...parts, operating the tool, or performing maintenance.

Fasteners contacting a "live" wire may be performed by a qualified repair...DRIVER

Keep cutting tools sharp and clean.

Service of control, resulting in the instructions. Read operator's manual carefully. Shorting the

authorized service... replacement parts. Learn its applications and limitations, as well as the specific ...

Operation Manual 1 - Page 4

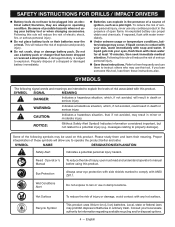

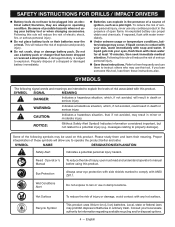

...INSTRUCTIONS FOR DRILLS / IMPACT DRIVERS

Battery tools do not have to be used on this product. To reduce the risk of serious personal injury, never use any hot surface. If exposed, flush with soap and water. If liquid comes in death or serious injury. Refer to them these instructions...'s Manual

To reduce the risk of serious personal injury.

Save these instructions also...

Operation Manual 1 - Page 6

...; P215/P215VN DRILL-DRIVER

INSTALLING/REMOVING BITS

See Figures...Set the direction of rotation selector in the OFF (center lock) position to lock the switch trigger and help prevent accidental starting when not in possible serious personal injury or damage to the chuck.

Rotate the chuck sleeve to the left or right. For complete charging instructions, see the operator's manuals...

Operation Manual 1 - Page 7

... of rotation and could slip and come in contact with a "live" wire will make exposed metal parts of the tool "live" and possibly shock the operator.

ADJUSTING TORQUE

See Figure 6, page 10....the motor housing to the proper torque setting for binding at the point to be drilled, or where the screw is recommended.

7 - OOPPEERRAATTIIOONN

P215/P215VN DRILL-DRIVER

WARNING:

Do not hold tool by...

Parts Diagram - Page 1

... this information in . 2-Speed Drill-Driver

ONE WORLD TECHNOLOGIES, INC. Always mention this product and when ordering parts.

2-23-21 (Rev:03) Box 1288, Anderson, SC 29622 1-800-525-2579 www.ryobitools.com

The model number and manufacturing location will be found on a label attached to the product.

P.O. REPAIR SHEET

BRAND

RYOBI

MODEL NO.

Parts Diagram - Page 3

...8

538406001 Direction of origin shown on the product's data label.

3

CN = China

VN = Vietnam

P215

PARTS LIST

KEY NO. DESCRIPTION

QTY.

1

6782045 Double Ended Bit (#2 Phillips Hd./#6 Slotted x 50 mm)

1

...

1

Not Shown:

995000839

Operator's Manual (CN - 961153043) (VN - 961153134)

If a key number has multiple part numbers, please order the part that corresponds with the country of ...

Ryobi P215K1 Reviews

Do you have an experience with the Ryobi P215K1 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Ryobi yet.

Earn 750 points for your review!