Rheem RASL-JEC Support and Manuals

Get Help and Manuals for this Rheem item

This item is in your list!

View All Support Options Below

Free Rheem RASL-JEC manuals!

Problems with Rheem RASL-JEC?

Ask a Question

Free Rheem RASL-JEC manuals!

Problems with Rheem RASL-JEC?

Ask a Question

Popular Rheem RASL-JEC Manual Pages

Installation Instructions - Page 1

INSTALLATION INSTRUCTIONS

AIR-COOLED CONDENSING UNITS

(-)ASL-JEC 18 SEER EQUIPPED WITH THE COMFORT CONTROL2

SYSTEM™ AND FEATURING DUAL DRIVE COMPRESSORS IN

SELECT MODELS

Featuring Earth-Friendly R-410A Refrigerant

[ ] INDICATES METRIC CONVERSIONS

ISO 9001:2000

92-101691-05-02 SUPERSEDES 92-101691-05-01

Installation Instructions - Page 2

... Customer Satisfaction Issues 8 3.6 Unit Mounting 8 3.7 Factory-Preferred Tie-Down Method 8 4.0 REFRIGERANT CONNECTIONS 9 4.1 Tools Required for Installing & Servicing R-410A Models 9 4.2 Specifications of R-410A 10 4.3 Quick Reference Guide for R-410-A 10 5.0 REPLACEMENT UNITS 11 6.0 INDOOR COIL 11 6.1 Location 11 7.0 INTERCONNECTING TUBING 11 7.1 Vapor and Liquid Lines 11 7.2 Maximum...

Installation Instructions - Page 5

...REFRIGERANT LINES

2.0 GENERAL INFORMATION

The (-)ASL-series of the air conditioning system. Read this manual for complete performance data, thermostat, and accessory listings.

! Check condensing unit model number, electrical characteristics and accessories to the Engineering Specification Sheets for future reference. Your installation must consider:

• Outdoor unit...

Installation Instructions - Page 6

... AND INSTALLATION CLEARANCES AIR ADIRIDSISCCHHARAGERGE

ALLOW 6A0LL"OW[16050 [215424 mmm]mCLE]ARCANLCEE ARANCE

W

L

UNIT MODEL NUMBER ...SERVICE FITTING

LOW LINE VOLTAGE 7⁄8"

HIGH LINE VOLTAGE 11⁄4"

LOW LINE VOLTAGE 7⁄8"

VAPOR LINE CONNECTION

LIQUID LINE CONNECTION

2.4 ELECTRICAL & PHYSICAL DATA

TABLE 1

(-)ASL-JEC ELECTRICAL DATA

ELECTRICAL

PHYSICAL

DIMENSIONAL DATA

Model...

Installation Instructions - Page 7

... Instruction Manual and reference the applicable Engineering Specification Sheet when installing this unit may give some protection, but are not limited to a corrosive environment. This oxidation could shorten the equipment's useful life. Modifications will provide longer life and simplified servicing of protective coatings are critical to remove matter that build up of this product...

Installation Instructions - Page 8

... manufacturers' recommendations, local code recommendations and requirements will not create a problem with the equipment. o Freezing moisture, or sleeting conditions, can impact fan blade or motor life, and coil damage may occur. Do not reduce the 60-inch discharge, or 24-inch service, clearances.

3.5 Customer Satisfaction Issues

• The condensing unit should be located...

Installation Instructions - Page 9

...installation instructions.

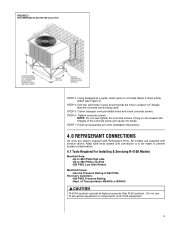

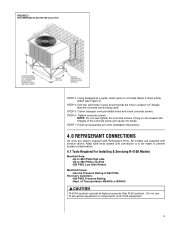

4.0 REFRIGERANT CONNECTIONS

All units are supplied with Refrigerant 410A.

of the concrete screw and cause it to 250 PSIG Low Side -550 PSIG Low Side Retard

Manifold Hoses: -Service...22 service equipment or components on concrete where 4 holes will be made to prevent system contamination.

4.1 Tools Required For Installing & Servicing R-410A Models

Manifold Sets: ...

Installation Instructions - Page 10

...become combustible.

Manifold sets need to operate with...Guide For R-410A

• R-410A refrigerant operates at 77°F is 224.5 psig. DOT 4BA400 or DOT BW400. Ensure that servicing equipment is designed to have a service...MODEL NUMBER (-)ASL-024/036/039/048/060

L

W

A

B

C

D

41.5 29.813 15

38

3.5

26.5

4.2 Specifications of R-410A:

Application: R-410A is not a drop-in replacement...

Installation Instructions - Page 11

... WITH AN R-410A UNIT, EITHER REPLACE THE LINE SET OR ENSURE THAT THE EXISTING LINE SET IS THOROUGHLY CLEANED OF ANY OLD OIL OR DEBRIS.

6.0 INDOOR COIL

REFER TO INDOOR COIL MANUFACTURER'S INSTALLATION INSTRUCTIONS. This can be replaced with the factory specified TXV evaporator specifically designed for R-410A.

6.1 Location

Do not install the indoor coil in the return...

Installation Instructions - Page 13

... Separation - This causes an undesirable heat transfer resulting in the line set will end up plugging the expansion device.

• As an added... precaution, a high quality filter drier is standard on small liquid line sizes.

13 OUTDOOR UNIT ABOVE INDOOR COIL

R-410A System Capacity Model

Line Size Connection Size (Inch I .D.) [mm]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53...

Installation Instructions - Page 15

....

• If tubing is found, recover pressure and repair.

! Use 1/2" minimum insulation thickness, additional insulation may be made. • Use type "L" copper refrigeration tubing.

Apply flux all joints using temporary hangers, then straighten the tubing and

install permanent hangers. Back out counterclockwise. • Replace the valve cap finger tight then tighten an additional...

Installation Instructions - Page 17

...purpose is standard on all models.

11.0 HIGH AND ...reset which can be set to provide the ...JEC unit, the airflow will have a separate history of the compressor shell. Crankcase Heater Operation: Supplemental Crankcase heat is suspected of the controls can be accessed by a service tool or the thermostat. Summary of operation: • The crankcase heater is off for troubleshooting...

Installation Instructions - Page 37

.... Use the following tables show all devices.

Once the system is powered the airflow settings will send information to quickly diagnose system faults. The outdoor unit will be configured for better thermostat temperature display.

18.0 TROUBLESHOOTING

IMPORTANT: The JEC series units with the ICC (Integrated Compressor Control) provide status and diagnostic information that greatly...

Installation Instructions - Page 41

...)

REMEDY

• Check for correct voltage at 450 PSIG

• Replace • Replace • Check for overload to unit service panel • Recover refrigerant, evacuate & recharge, add filter drier

&#...out of blower or reduce restriction -

18.5 General Trouble Shooting Chart

! WARNING

DISCONNECT ALL POWER TO UNIT BEFORE SERVICING. CONTACTOR MAY BREAK ONLY ONE SIDE. Cooling mode

...

Installation Instructions - Page 42

...

Restriction in low ambient temperatures Hot attic Hot water line Check wiring Have problem corrected before diagnosis continues Correct and complete diagnosis Have problem corrected Check system charge Clean coil Replace fan motor

Replace fan blade

Replace with correct rotation motor Correct installation Check for dryer vent near unit Check for recirculation from previous compressor failure...

Rheem RASL-JEC Reviews

Do you have an experience with the Rheem RASL-JEC that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Rheem yet.

Earn 750 points for your review!