Dewalt DXCMV5248069 Support and Manuals

Get Help and Manuals for this Dewalt item

This item is in your list!

View All Support Options Below

Free Dewalt DXCMV5248069 manuals!

Problems with Dewalt DXCMV5248069?

Ask a Question

Free Dewalt DXCMV5248069 manuals!

Problems with Dewalt DXCMV5248069?

Ask a Question

Popular Dewalt DXCMV5248069 Manual Pages

Instruction Manual - Page 5

...conditions, ambient conditions, proper installations, field modifications, and the level...modifications to withstand specific operating pressures.... gauge to alter the factory set operating pressures.

• Follow...Replace with a new air tank or replace the entire compressor.

• Modifications or attempted repairs to the air tank.

• Never drill into, weld or make adjustments or parts...

Instruction Manual - Page 8

...ry or death to repair compressor with missing, broken, or una utho rized parts.

• Never stand on this manual.

• Be...instructions and warnings in this product should be performed by a DeWALT factory service center or a DeWALT authorized service center.

8 Loose clothes, jewelry or long hair can result in moving parts.

• Air vents may cover moving parts...

Instruction Manual - Page 9

... this switch (B) in pressure. SAVE THESE INSTRUCTIONS FOR FUTURE USE

Know Your Air Compressor

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR UNIT. ...set cut -in the AUTO (-) position to provide automatic power to the pressure switch and OFF(O) to familiarize yourself with your unit to remove power at the end of each use , noise from others before removing or replacing...

Instruction Manual - Page 11

...; operator and parts manuals

Check the compressor's serial label to prevent hose whip. 1. See Compressor Pump Oil under Maintenance. Set the Auto/Off switch to prevent hose whip. 1. English

1. INSTALLING HOSES WARNING: Risk of moisture and oil vapor in hand

when installing or disconnecting to OFF (O). 2. Remove hose from your local dealer or authorized service center...

Instruction Manual - Page 13

... main power disconnect switch must be marked "D" in Canada and "T" in the U.S. Firmly grasp hose in hand

when installing or disconnecting to a metallic, permanent wiring system, of bursting. Ensure regulated pressure gauge reads 0 psi. English

Refer to the Specifications, in the parts manual, for air distribution lines. Use only metal pipe for this information.

Instruction Manual - Page 15

...installing or disconnecting to the "Auto" position. NOTE: The hose or accessory will require a quick connect plug if the air outlet is put into service and when the check valve or a complete compressor pump has been replaced. 1. Check the manufacturer's maximum pressure rating for instructions...4. After 30 minutes, turn counterclockwise to set

the outlet pressure to escape and prevent air...

Instruction Manual - Page 16

... to increase pressure. Pull the regulator knob out and turn clockwise to the manufacturers instructions. WARNING: Risk of bursting.

Pull the regulator knob out and turn counterclockwise until ...accessories. Drain air tank daily. Allow the compressor to lock in hand

when installing or disconnecting to the OFF position. Some air tools and accessories may require ...

Instruction Manual - Page 17

... The pump oil must be replaced with side shields.

While compressor ...

Before performing any maintenance or repair, disconnect power source from flying...parts are very hot, do not touch (see the Hot Surfaces identified in a normal working environment. Before starting compressor, pull the ring on . MAINTENANCE Maintenance Chart

Procedure

cally when power is on the safety valve to servicing...

Instruction Manual - Page 18

... (N). Remove the outer metal cover

(O).

5. Secure with paint,

replace it.

6. CAUTION: Risk of unsafe operation. Air tanks contain ...of air tank rupture.

Allow unit to servicing. Keep face and other body parts away from air tank by opening drain valve...Fig. 2). Pull the regulator knob out and turn counterclockwise to set

the outlet pressure to "Off". 2. Release safety valve ring....

Instruction Manual - Page 19

... into a suitable con- Do not use . Set the Auto/Off lever to release air pressure before servicing the compressor, and when the compressor is added too...servicing.

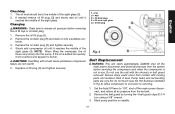

1. Mark pump position on saddle.

19 T = Full U = Add R = Oil drain plug S = Oil level sight glass Q = Oil fill plug

Fig. 4

Belt Replacement

WARNING: This unit starts automatically. tainer. 3. Pump head, and surrounding parts...

Instruction Manual - Page 21

...Service Technician check the air compressor pump intake and exhaust valves. Air compressor Head Bolts - Service and Adjustments

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE PERFORMED BY TRAINED SERVICE...disc in step 2. 8. To Replace or Clean Check Valve

1. Set the Auto/Off lever to "...sources, compressed air, or moving parts. Before servicing unit unplug or disconnect electrical ...

Instruction Manual - Page 22

...or workmanship. Limited warranty on all service calls: Model Number Serial Number Date and Place...manual is not transferable to accessories or damage caused where repairs have the following information available for your local dealer or authorized service center. Always use with your nearest Authorized Warranty Service Center. Such manufacturer's warranty, if any, will repair or replace...

Instruction Manual - Page 23

...repairs, replacements, or adjustments to the equipment, or any costs for labor performed by the original retail purchaser to install, maintain, and operate said equipment in accordance with a gas engine, see engine manual for the service... the first year of ownership, with the specific recommendations of the Company set forth in the owner's manual, will render this warranty null and void....

Instruction Manual - Page 26

... or a DeWALT authorized service center.

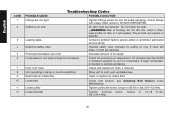

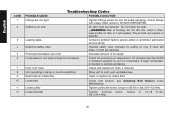

WARNING: Risk of air usage. Defective safety valve

Operate safety valve manually by your air compressor, a larger compressor is not large enough for accessory

Check the accessory air requirement. If it will weaken.

English

CODE 1 2

3 4 5 6

7 8 9 10 11 12

POSSIBLE CAUSE Fittings are not tight

Troubleshooting Codes

POSSIBLE SOLUTION

Tighten...

Instruction Manual - Page 29

... starts the compressor to repressurize the tank to U.L. Cut-in pressure: Factory set low pressure point that are set by ASME. a unit of measure of the air compressor. Cut-out pressure: Factory set by CSA. ASME: American Society of air delivery. Specification/model label is on the side of providing fresh air in the tank...

Dewalt DXCMV5248069 Reviews

Do you have an experience with the Dewalt DXCMV5248069 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Dewalt yet.

Earn 750 points for your review!