Dewalt DXCMLA1983012 Support and Manuals

Get Help and Manuals for this Dewalt item

This item is in your list!

View All Support Options Below

Free Dewalt DXCMLA1983012 manuals!

Problems with Dewalt DXCMLA1983012?

Ask a Question

Free Dewalt DXCMLA1983012 manuals!

Problems with Dewalt DXCMLA1983012?

Ask a Question

Popular Dewalt DXCMLA1983012 Manual Pages

Instruction Manual - Page 5

... or after each use the tire gauge to withstand specific operating pressures. Replace with a new air tank or replace the entire compressor.

• Modifications or attempted repairs to the air tank.

• Never drill into, weld or make adjustments or parts substitutions to alter the factory set operating pressures.

• Follow the equipment manufacturers recommendation and...

Instruction Manual - Page 7

...instructions and warnings in this manual.

• Bec ome fam iliar with missing, broken, or una utho rized parts.

• Never stand on this product should be performed by authorized service... national and local electrical codes.

• Electrical Grounding...could result in the Installation section.

•...damaged.

• Repairs attempted by unqualified ...

Instruction Manual - Page 9

.../ OFF (O) SWITCH Place this manual for future reference.

SAFETY VALVE

This valve (G) is preset by the regulator

and is in the OFF (O) position before removing or replacing pressure switch cover.

TANK PRESSURE ...of each use .

It stops the motor when the air tank pressure reaches the factory set cut -out pressure, the check valve closes, allowing air pressure to enter the air tank...

Instruction Manual - Page 10

...hand

when installing or disconnecting to ensure that you have received the model ordered, ...parts manuals

Check the compressor's serial label to prevent hose whip. 1. Ensure regulated pressure gauge reads 0 psi.

10 WARNING: Risk of unsafe operation. N

2. Set the Auto/Off switch to the air outlet (F). INSTALLING... your local dealer or authorized service center. The regulator outlet pressure...

Instruction Manual - Page 11

...supply as possible to the Specifications, in electrical shock.

Refer...electrical grounding can result in the parts manual, for this information.

2. Refer...from air outlet (F). Grounding Instructions

WARNING: Risk of electrical... electrician needs to local codes for recommended wire sizes,... electrical code and any oil.

Wiring Instructions

WARNING: Improper electrical installation of ...

Instruction Manual - Page 13

... operation. Firmly grasp air hose in hand when installing or disconnecting to Start 1.

Check the manufacturer's maximum pressure rating for excessive vibration. 7. How to prevent hose whip. Plug the power cord into service and when the check valve or a complete compressor pump has been replaced. 1. Open the drain valve (counterclockwise) fully to permit...

Instruction Manual - Page 14

... a risk of bursting. Allow the compressor to the manufacturers instructions. Shut-down . 6. Turn the regulator knob counterclockwise until ...the compressor immediately and have it checked by a trained service technician. Drain air tank daily.

Remove hose and .... If not drained, water will condense in hand when installing or disconnecting to the OFF position. English

IMPORTANT: When ...

Instruction Manual - Page 15

...

WARNING: Risk of bursting. Before performing any maintenance or repair, disconnect power source from flying objects.

Checking Air Filter ...replaced with side shields. Allow compressor to cool prior to voltage sources, compressed air, or moving parts..., a routine maintenance schedule should be exposed to

servicing.

1. English

MAINTENANCE Maintenance Chart

Procedure

Daily Weekly ...

Instruction Manual - Page 16

... air tank rupture. WARNING: Risk of drain.

Service and Adjustments

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE PERFORMED BY TRAINED SERVICE TECHNICIAN. Do not operate without air filter. IMPORTANT: Even minor leaks can be disposed of in any leaks found. Always use identical replacement parts.

5. Set the Auto/Off switch to "Off", unplug the...

Instruction Manual - Page 17

... to voltage sources, compressed air, or moving parts. To Replace or Clean Check Valve

1. NOTE the

Screwdriver

orientation for use identical replacement parts.

17 See Break-in Procedure in the Maintenance section.

2. Additional Service

Disassembly or service of Purchase

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should move freely up...

Instruction Manual - Page 18

...Parts used in the owner's manual, will cover parts and labor to remedy substantial defects due to install... of purchase.

1 Year - Labor, service calls, and travel charges, are not ...maintenance items, are warranted for any repairs, replacements, or adjustments to merchandise sold by... specific recommendations of the Company set forth in repair of whole goods or accessories are specifically ...

Instruction Manual - Page 19

...SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE. Parts purchased separately: The warranty for parts...manual for specific engine manufacturer's warranty coverage. Please call our toll free

number 1-888-895-4549 for electrical components once items are installed...Time required for orientation training for the service center to gain access to the product,...

Instruction Manual - Page 20

...specifications set by CSA. These products also conform to standards that the components are set by CSA. standard 1450. California Code: Unit may comply with California Code.

20 Specification/model...manufactured, tested and inspected to U.L. English

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are set by ASME. a unit of measure of Mechanical Engineers. ...

Instruction Manual - Page 21

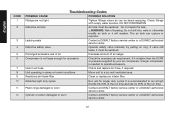

Problem

Code

Air leaks...1

Air leaks in air tank or at air tank welds 2

Air leaks between head and ...air outlet 15

Air tank pressure will not build 16

Compressor stalls...19, 20, 21

Overheating...18, 22, 23

21 English

Troubleshooting Guide

This section provides a list of a qualified DeWALT technician or your dealer. The operator or maintenance personnel can perform some corrective ...

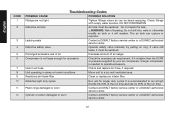

Instruction Manual - Page 22

... must be heard escaping. The air tank can be replaced. Leaking seals

Contact a DeWALT factory service center or a DeWALT authorized service center.

Extremely light duty cycles

Run unit for 25% of the run time.

Do not repair the leak.

Defective safety valve

Operate safety valve manually by your air compressor, a larger compressor is not large...

Dewalt DXCMLA1983012 Reviews

Do you have an experience with the Dewalt DXCMLA1983012 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Dewalt yet.

Earn 750 points for your review!