Singer 5511 SCHOLASTIC Support Question

Find answers below for this question about Singer 5511 SCHOLASTIC.Need a Singer 5511 SCHOLASTIC manual? We have 1 online manual for this item!

Question posted by kimborland on March 16th, 2014

Stitch Selection

I've just taken my machine out of the box, I can't get it to make the stitfch labeled "J" in the manual.

Current Answers

Related Singer 5511 SCHOLASTIC Manual Pages

Similar Questions

Needle Won't Go All The Way Up In Slot After Replacing It.

(Posted by lgardner064 9 months ago)

Jammed Sewing Machine

How can i unjam my machine the manual wheel will not turn foward or backward

How can i unjam my machine the manual wheel will not turn foward or backward

(Posted by msdebra3 4 years ago)

Stitch Selection Dial Will Not 'seat' On Straight-stitch.

The selection dial will "seat" on corresponding special stitches, but not in the "gray" selections w...

The selection dial will "seat" on corresponding special stitches, but not in the "gray" selections w...

(Posted by lynnebennett 8 years ago)

Beeping From Singer Sewing Machine Stylist Ii 5625

My sewing machine will beep and stop sewing after three inches of sewing. I have taken it to be repa...

My sewing machine will beep and stop sewing after three inches of sewing. I have taken it to be repa...

(Posted by arusheria 9 years ago)

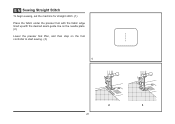

How To Thread The Serger On A 5511

Singer Sewing Machine

cannot find information on how to thread the serger that ispart of the sewing machine

cannot find information on how to thread the serger that ispart of the sewing machine

(Posted by Anonymous-93910 11 years ago)