Singer 5511 SCHOLASTIC Support Question

Find answers below for this question about Singer 5511 SCHOLASTIC.Need a Singer 5511 SCHOLASTIC manual? We have 1 online manual for this item!

Question posted by lgardner064 on June 27th, 2023

Needle Won't Go All The Way Up In Slot After Replacing It.

The person who posted this question about this Singer product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by SonuKumar on June 27th, 2023 9:01 PM

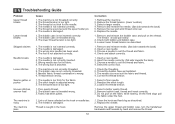

If the needle on your Singer 5511 SCHOLASTIC sewing machine is not going all the way up in the slot after replacing it, there are a few potential causes and solutions to consider:

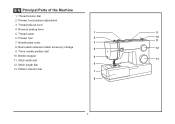

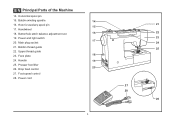

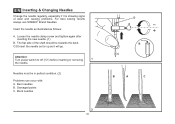

- Check the needle compatibility: Ensure that you have installed the correct needle type and size for your machine. The Singer 5511 SCHOLASTIC typically uses standard sewing machine needles, but it's essential to double-check the compatibility. Make sure the needle is fully inserted and tightened according to the machine's instructions.

- Verify the needle positioning: Examine the needle position and make sure it is inserted correctly. The flat side of the needle shaft should be facing the back of the machine, and the needle should be pushed up as far as it will go. If the needle is not fully inserted, it may not reach the highest position.

- Inspect for any obstructions or debris: Examine the needle area and the throat plate for any thread, lint, or other debris that might be obstructing the needle's movement. Use a small brush or a vacuum cleaner with a narrow nozzle to remove any debris. Cleaning the machine regularly is important to prevent build-up that can affect needle movement.

- Check for a bent needle or damaged needle clamp: Inspect the needle to ensure it is not bent or damaged. A bent needle can cause interference with the upward movement. Similarly, check the needle clamp or holder to ensure it is not bent or misaligned. If there is any damage, it may need to be repaired or replaced.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Singer 5511 SCHOLASTIC Manual Pages

Similar Questions

Jammed Sewing Machine

How can i unjam my machine the manual wheel will not turn foward or backward

How can i unjam my machine the manual wheel will not turn foward or backward

(Posted by msdebra3 4 years ago)

I Get E7 Error Message On My Singer Model 7258 Sewing Machine. There Is No Refe

Error message E7 is up on my Singer Stylist model 7258 sewing machine. It is not working at all. I t...

Error message E7 is up on my Singer Stylist model 7258 sewing machine. It is not working at all. I t...

(Posted by ebellamybellamy9 5 years ago)

Beeping From Singer Sewing Machine Stylist Ii 5625

My sewing machine will beep and stop sewing after three inches of sewing. I have taken it to be repa...

My sewing machine will beep and stop sewing after three inches of sewing. I have taken it to be repa...

(Posted by arusheria 9 years ago)

Where Do I Get Instructions For Useing My Cutting Too.

I bought the cutting too with the machine but have no instructions for using it. I have a singer 551...

I bought the cutting too with the machine but have no instructions for using it. I have a singer 551...

(Posted by msbingo 10 years ago)

How To Thread The Serger On A 5511

Singer Sewing Machine

cannot find information on how to thread the serger that ispart of the sewing machine

cannot find information on how to thread the serger that ispart of the sewing machine

(Posted by Anonymous-93910 11 years ago)