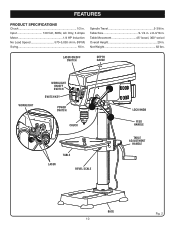

Ryobi DP102L Support Question

Find answers below for this question about Ryobi DP102L.Need a Ryobi DP102L manual? We have 4 online manuals for this item!

Question posted by rjbsilverking on March 4th, 2014

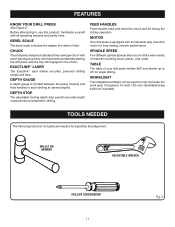

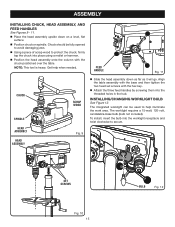

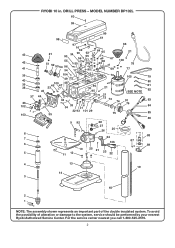

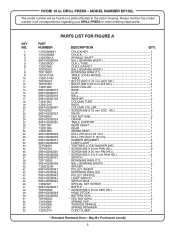

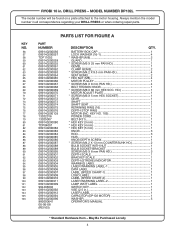

How To Replace A Depth Stop Ring On The Dp102l What Parts Are Needed

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to replace it?

Current Answers

Related Ryobi DP102L Manual Pages

Similar Questions

Machine Is Not Turning On When Inserting Key And Pushing Up Key Pops Out?

(Posted by estherflam 2 years ago)

I Did Not Pay Attention To What Wires Go Where On Switch Replacement.

I do not understand the symbols on the electrical schematics for the DP102L drill press

I do not understand the symbols on the electrical schematics for the DP102L drill press

(Posted by jajzksb 8 years ago)

Where Are The Positive Stops Inside The Cabinet? Need To Make Adjustments For

I need to make adjustments for a 90 degree cut.

I need to make adjustments for a 90 degree cut.

(Posted by rnicot 10 years ago)

Dp102l Quit Working

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting...

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting...

(Posted by chief4070 12 years ago)