Husqvarna 365 Support Question

Find answers below for this question about Husqvarna 365.Need a Husqvarna 365 manual? We have 2 online manuals for this item!

Question posted by Jlnayler on June 2nd, 2015

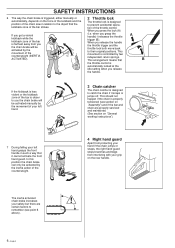

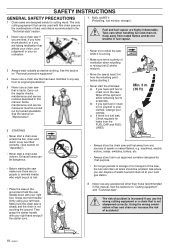

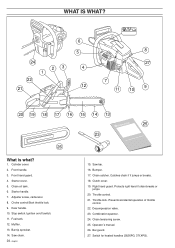

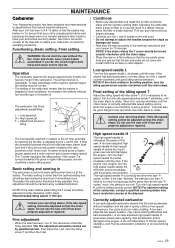

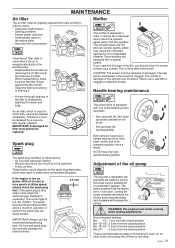

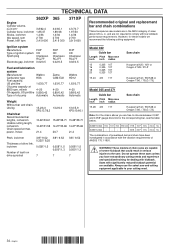

Husqvarna Chainsaws 365 Special Manual How Do U Adjust Chain Oil

The person who posted this question about this Husqvarna product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by TommyKervz on June 2nd, 2015 6:52 AM

Follow the instructions on this video here https://www.youtube.com/watch?v=H6YcOnFR1OU

Related Husqvarna 365 Manual Pages

Similar Questions

Husqvarna 353 E-tech Manuals

My 353 e tech leaks bar oil rapidly when not in use, is there a simple adjustment?

My 353 e tech leaks bar oil rapidly when not in use, is there a simple adjustment?

(Posted by timijo 7 years ago)

Snow Thrower St227p Manual Does Not Illustrate Where Oil Drain Plugor Spark Plu

Manual does not illustrate where oil drain plug or spark plug is locatedNo luck finding anything on ...

Manual does not illustrate where oil drain plug or spark plug is locatedNo luck finding anything on ...

(Posted by thomasgordon 8 years ago)

Trouble Setting The Throttle Spring On Gas Chainsaw Husqvarna 365

i was replacing d gas line and somehow the throttle stop functioning so i took it apart and now i do...

i was replacing d gas line and somehow the throttle stop functioning so i took it apart and now i do...

(Posted by figueroajoanne 9 years ago)

Dry Chain

I've cleaned the oil tank and bar. Still no chain oil flowing. What now?

I've cleaned the oil tank and bar. Still no chain oil flowing. What now?

(Posted by mitchc 11 years ago)