Hitachi C8FSE Support Question

Find answers below for this question about Hitachi C8FSE - 8-1/2" Sliding Compound Miter Saw.Need a Hitachi C8FSE manual? We have 1 online manual for this item!

Question posted by weishapple on September 12th, 2011

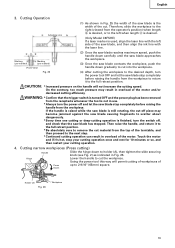

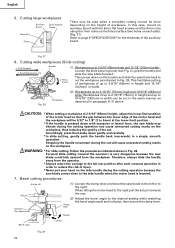

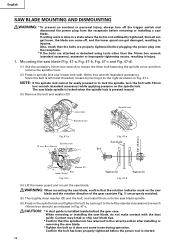

Changing Saw Blade

Where are instructions on changing a saw blade on a Hitachi C8FSE saw? Thanks

Current Answers

Related Hitachi C8FSE Manual Pages

Similar Questions

What's The Name Of This Part? Hikoki C8fse

https://www.reddit.com/r/Tools/comments/y36tbl/whats_this_part_called_hikoki_c8fse/?utm_source=share...

https://www.reddit.com/r/Tools/comments/y36tbl/whats_this_part_called_hikoki_c8fse/?utm_source=share...

(Posted by ellieleaman 1 year ago)

How To Remove Back Cover On 8 Fsb Mitre Saw Rails

How do you get the back cover off on 8fsb mitre saw

How do you get the back cover off on 8fsb mitre saw

(Posted by Anonymous-170524 2 years ago)

How To Adjust Cut Depth Hitachi 10 Compound Miter Saw Manual

(Posted by dbrag 10 years ago)

I Require A Vise Assembly For A Hitachi C8fse Slide Compound Saw, Please Help

I have an Hitachi C8FSE Slide Compound Saw and wish to purchase a Vise Assembly, can anybody help?

I have an Hitachi C8FSE Slide Compound Saw and wish to purchase a Vise Assembly, can anybody help?

(Posted by davaki 10 years ago)

Where Can I Get A Free Manual On The Hitachi C12rsh 12' Slide Compound Miter Saw

(Posted by kathy86883 14 years ago)