Dewalt DWE7491RS Support Question

Find answers below for this question about Dewalt DWE7491RS.Need a Dewalt DWE7491RS manual? We have 2 online manuals for this item!

Question posted by Hypockets57 on October 26th, 2023

Material Support

material support does not sit flat. No matter what slot- new just ou

Current Answers

Answer #1: Posted by SonuKumar on October 26th, 2023 10:08 PM

A fence that is not square to the table or at 90 degrees to the table surface, should be an easy fix. There's an adjustment in the T head. A fence that down not sit flat all across the table means either the fence is curved on the bottom or the table top is curved/warped.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

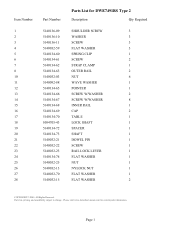

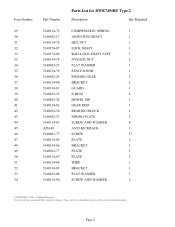

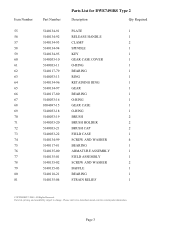

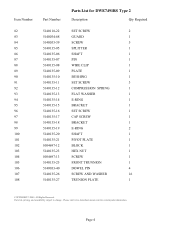

Related Dewalt DWE7491RS Manual Pages

Similar Questions

Support Arms

Ounce I slide the support arms in.How do I take them all the way out?

Ounce I slide the support arms in.How do I take them all the way out?

(Posted by jstevens057 2 years ago)

Extension / Support Arms On A Dwx726: When 1 Arm Retracts The Other Arm Extends

(Posted by Anonymous-169129 2 years ago)

Trim Gun Support

my dealt d51276 ty2 when I connect air driver perues and does not return

my dealt d51276 ty2 when I connect air driver perues and does not return

(Posted by malcolmmx320 8 years ago)

Rip Fence Lock

How do you adjust the locking system for the rip fence?

How do you adjust the locking system for the rip fence?

(Posted by kawtool 9 years ago)