Craftsman 21833 Support Question

Find answers below for this question about Craftsman 21833 - Professional Contractor Table Saw.Need a Craftsman 21833 manual? We have 1 online manual for this item!

Question posted by semid09 on March 10th, 2014

I Have A Pgt 9000 54' 26hp Lawn Tractor Model 944.609312 And I Have No Spark So

Pulled the spark plugs and no spark and also dry. What do I try to look for, how do I test the coil

Current Answers

Answer #1: Posted by freginold on March 21st, 2014 3:37 AM

Hi, you can use a spark plug tester to find out if the problem is with the spark plug itself or with the signal getting to the spark plug. Attach the spark plug tester in between the spark plug boot and the spark plug (one end will plug into the boot, one end will plug into the spark plug). Then start the engine. If you see a spark or light in the tester, the signal is fine, so it's just a bad spark plug. If there is no spark or light, make sure everything is connected correctly, but it may be a bad coil.

Related Craftsman 21833 Manual Pages

Similar Questions

Changing Table Saw Motor To 240v

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagra...

(Posted by mridude 9 years ago)

Craftsman Lawn Tractor Purchased On 4/21/14

Sears Sold Me This Tractor With A Dead Battery. It Was Replaced. Now I Have A Flat Fire Everytime I ...

Sears Sold Me This Tractor With A Dead Battery. It Was Replaced. Now I Have A Flat Fire Everytime I ...

(Posted by fgtussey 9 years ago)

Table Saw Model 218290

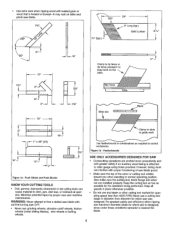

i need instruction to use sliding miter angles

i need instruction to use sliding miter angles

(Posted by shankarbn 9 years ago)

Model 351.221160 Craftsman Premium Hybrid Table Saw

How do you separate the granite top from the base. The bolts are not visible on the front?

How do you separate the granite top from the base. The bolts are not visible on the front?

(Posted by tjmcleary1 11 years ago)

Is A Table Saw Motor From A Model 21807 Compatible With Other Saws?

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

will the 3HP 15 amp motor from a model 21807 mount properly on a model 137.248880 table saw (both ar...

(Posted by deannarandy 13 years ago)