Craftsman 21833 Support Question

Find answers below for this question about Craftsman 21833 - Professional Contractor Table Saw.Need a Craftsman 21833 manual? We have 1 online manual for this item!

Question posted by mridude on September 22nd, 2014

Changing Table Saw Motor To 240v

I have a 10" Craftsman table saw model #152221140. Lost the cover to the wiring which has the diagram to switch from 100v to 240v. I just need the wiring diagram so I can switch to 240V

Current Answers

Related Craftsman 21833 Manual Pages

Similar Questions

Table Saw Model 218290

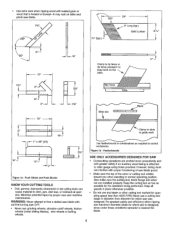

i need instruction to use sliding miter angles

i need instruction to use sliding miter angles

(Posted by shankarbn 9 years ago)

Repairing Broken Drive Belt On Craftman Band Saw Model 351.214190

How To Remove The Lower Wheel On Craftman Band saw Model 351.214190. Because The Drive Belt Is broke...

How To Remove The Lower Wheel On Craftman Band saw Model 351.214190. Because The Drive Belt Is broke...

(Posted by AVERBECK 10 years ago)

Saw Jams

I have a Craftsman 10" Professional Contractor table saw and I can not even cut through 1/2" boards ...

I have a Craftsman 10" Professional Contractor table saw and I can not even cut through 1/2" boards ...

(Posted by bduffy17374 11 years ago)

Model 351.221160 Craftsman Premium Hybrid Table Saw

How do you separate the granite top from the base. The bolts are not visible on the front?

How do you separate the granite top from the base. The bolts are not visible on the front?

(Posted by tjmcleary1 11 years ago)

I Don't Have A Inpack Rench. How Can I Get The Bolt Off To Change The Blads

(Posted by Anonymous-72253 11 years ago)