Brother International XL-2027 Support Question

Find answers below for this question about Brother International XL-2027.Need a Brother International XL-2027 manual? We have 1 online manual for this item!

Question posted by Jldaspit on January 26th, 2018

The Pattern Selector Is Too Tight

Brother xl-2027 is in otherwise excellent condition but the pattern selector is not turning easily & the reverse bar isn't working. What can I do?

Current Answers

There are currently no answers that have been posted for this question.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Related Brother International XL-2027 Manual Pages

Users Manual - English - Page 2

CONTENTS

KNOWING YOUR SEWING MACHINE Principal parts Accessories

VARIOUS CONTROLS Pattern selector Electronic display Stitch length dial Reverse sewing button Foot controller Sew-light Free-arm model Twin needle Changing presser foot

THREADING THE MACHINE Winding the bobbin Lower threading Upper threading To draw up lower thread Tension controls

RELATIVE CHART OF SEWING FABRICS, NEEDLE AND THREAD ...

Users Manual - English - Page 3

... ELECTRONIC DISPLAY O PATTERN INDICATION PANEL

0 REVERSE SEWING BUTTON

Push for reverse stitching.

0 BALANCE WHEEL

Turn toward you to lower and raise the needle.

0 CLUTCH RELEASE KNOB

lib PATTERN SELECTOR Turn in any direction to... the upper tension. KNOWING YOUR SEWING MACHINE Principal parts

O BOBBIN WINDER DEVICE Winds the lower thread onto the bobbin.

For more details, see each page...

Users Manual - English - Page 4

...:0

14

16 17

20

.§4

RECOMMENDED LENGTH

PATTERN

1

2

3

4 5 6 7 8 9...Pattern Selector

0

3 •

MESSAGE

LCD-.wall 111111

2 3 4

6

OS OW MI •Nr

OM

C. VARIOUS CONTROLS Pattern selector

To select a stitch, simply turn the pattern selector located on the end of stitch length.

The following table represents the preset width of each stitch and the recommended range of the machine...

Users Manual - English - Page 5

...sewing guidance. When you wish to sew forward.

Stitch length dial

STITCH LENGTH

II

y 3

Fine

Coarse

Reverse sewing button

Foot controller

Sew-light

Depending on the foot controller when the machine is released, the machine will pick up the speed. Reverse sewing... sew forward. Electronic display

5

MESSAGE

i

MESSAGE MIR

Message key

Light

Heavy

LCD adjuster

Pattern ...

Users Manual - English - Page 6

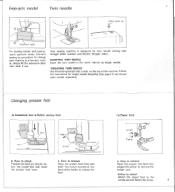

...for single needle threading (See pagel 1), but thread each needle separately. Your sewing machine is convenient. THREADING TWIN NEEDLE Set the extra spool pin into a hole on....

• How to attach

Attach the zipper foot to the

needle bar and fasten the screw.

8 Changing presser foot

(• Buttonhole foot • Button sewing foot)

Slot Push

sar

Screw

Removed

0

• How to attach ...

Users Manual - English - Page 7

... the metal finger into the shuttle race. I A1

r

Tighten

c Loosen

Slit Spring

Clutch Release Knob II

2. 9

THREADING THE MACHINE

Winding the bobbin

*Set a spool holder firmly so that the thread spool will not turn. Winding the bobbin (CONTINUED)

Lower threading

Slot Tension spring

Metal finger

Notch

0

0

z

4. Make sure to wind the thread...

Users Manual - English - Page 8

....

2. Pull the upper thread toward the back

of upper thread and with right hand, turn balance wheel toward you and the lower thread will come up from right to its high- Upper threading...

pool Holder

\-1

1. est position by turning the balance wheel toward you until the needle moves down and up again to left hand, hold the end of the machine.

12

a

To draw up Lever

'4;...

Users Manual - English - Page 9

...Bobbin

Ov

Decrease tension

13

Correct tension Reverse

Surface Correct tension is important because too much or too little tension will weaken your fabric. RELATIVE CHART OF SEWING FABRICS, NEEDLE AND THREAD

SEWING MATERIALS

NEEDLE SIZES

Fine tricot, Fine.... 2.

Locks appear on the reverse side of the fabric.

Raise number.

OO

Reverse Surface

■ Upper tension is too tight.

Users Manual - English - Page 10

... lift the presser foot.

2. Release the Reverse Sewing Button and start sewing in the fabric. 2. To prepare the machine for 3/8 inch (10 mm) from Machine 1. Raise the presser foot and turn - How to the left side.

4. Stop the machine at the end of presser foot.

3.

STRAIGHT AND ZIGZAG STITCHING

Straight stitch

Pattern 2 (Left needle position)

3 (Center needle position...

Users Manual - English - Page 11

...Pattern 4 (Stitch Width at 1.6 mm) 5 (Stitch Width at 3.6 mm) 6 (Stitch Width at "F" position, it produces the "SATIN STITCH" used for stretch fabrics.

I,

3. Sew on the width you will have a blind stitch hem as shown in Figure A.

Fold the fabric to sew... or decorative stitches.

,

BUILT-IN STITCHES

Blind hem stitch

Pattern

7 (Blind Hem Stitch) 11 (German Blind Stitch)

Stitch...

Users Manual - English - Page 12

... in illustration. Following the line of the presser foot as illustrated. tween F-1.

2. The elastic stitch is used for sewing a picot edge on the fabric.

2. This work requires a little tighter upper thread tension than the stitch pattern, trim away any excess fabric after stitching.

Place the elastic on a light weight fabric. 1. Position the fabric...

Users Manual - English - Page 13

... of the seams on the reverse side.

22 Scallop stitch

Pattern 12

Stitch Length F-1

21

Double action stitch

Pattern 13

Stitch Length 1-2

This machine produces decorative stitch (Scallop) automatically. Decorative stitches

Pattern 14 (Swan) 15 (Tulip)

Stitch Length 4

Fagoting stitch

Pattern 16

First needle drop

-1:14r---11 1.5 mm

Stitch Length 4

1. Sew scallop stitch along the edge...

Users Manual - English - Page 14

... stitching. Draw up

If

and sew 3/8 inch from the edge. Use buttonhole foot. 2. Using tailor chalk, mark the position of 1-4 as per the

illustration (D Stop the machine when bar tack is a simple process that you may use a zigzag stitch. Feather stitch

Pattern 18

Stitch Length 4

Rick-rack stitch

Pattern 20

Use this lever back slightly...

Users Manual - English - Page 15

...both ends of holes

1.6 mm (0.06 inch)

3.6 mm (0.14 inch)

4.8 mm (0.19 inch)

Pattern 4 5 6

2 Change the foot to cut through any stitching. 3. 25

HOW TO SECURE STITCHING ...from the machine. Distance of buttonhole as a protection against cutting bar tack stitching. At slow speed, sew approximately 10 stitches. 6. To secure stitching, turn the

material 90 degrees counterclockwise and sew 5-6 ...

Users Manual - English - Page 16

27

USING ATTACHMENTS AND APPLICATIONS

Zipper insertion

Pattern 3

Stitch Length 2-3

Foot Zipper Foot

Thumb screw O

Zipper foot is used to sew various types of zippers and can easily be positioned to right or left side of stitching. Sew alternately drawing the work gently away from you and pulling it toward you.

5. Baste the cut design to...

Users Manual - English - Page 17

...Put thumb screw through the work under the needle and lower the presser bar.

6. Set your sewing machine as possible.

5. Place the work at starting position by turning balance wheel and make a...29

Monogramming and Embroidering

Pattern 4 or 5 or 6

Stitch Length At any position

Foot Remove

Others Darning plate

Nre

PREPARATION FOR MONOGRAMMING AND EMBROIDERING 1. Sew, moving hoop slowly...

Users Manual - English - Page 18

... must always be straight and sharp for smooth sewing.

2. Changing the bulb

• Remove the power supply plug from 3. o

X

X

X

( A„

1. m no 11. Loosen the screw.

2. Remove the face plate from the outlet. Inserting the ... foot and loosen the screw.

2. To check if needle is bent, place flat side of needle down as it will go against the needle stopper. machine.

0

4.

Users Manual - English - Page 19

...Face Plate

• OIL 2 TO 3 DROPS TO THE POINTS MARKED • After oiling, run the machine fast without thread. • Be sure to its highest position. 2. Take out the bobbin case. 4....inside. Cleaning

• Remove the power supply plug from the outlet. • Lint and dust easily accumulate.

Retaining ring

Hook

a

Driver

Latch lever

Race body

Retaining ring

0

33 a

HOW TO ...

Users Manual - English - Page 20

...oiling

No -

-Page33

-N.-Page34

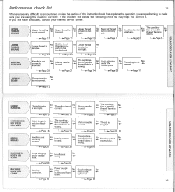

MACHINE DOES NOT START

Use foot controller. No

Ir

Power supply plug

No

is too tight.

No Thread is bent or...machine correctly.

Needle is tangled. thread/fabric is not correct.

UPPER THREAD BREAKS

LOWER THREAD BREAKS

SKIPPED STITCHES

LOOP IN SEAM

Upper threading No Upper thread is

is

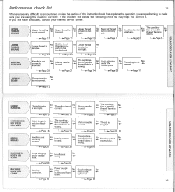

wrong. Performance check list

35

Whenever sewing...

Users Manual - English - Page 21

... 8 32 31 33 30 28 22 21 20 22 23 6 7 10 29

Oiling Overedging stitch Pattern selector Performance check list Principal parts Relative chart of sewing fabrics, needle and thread Repacking the machine Reverse sewing button Rick-rack stitch Scallop stitch Sew-light Shell tuck Stitch length dial Straight stitch Tension controls To draw up lower thread...

Similar Questions

Can I Lower The Feed Dogs On A Brother Sewing Machine Xl 3010 Model

(Posted by Vibobby 9 years ago)

How To Thread A Brother Sewing Machine Xl-5500

(Posted by CAB14mitk 9 years ago)

How To Use A Brother Sewing Machine Xl-2600i Setting Stitch And Tension

(Posted by v007CCdu 10 years ago)

How To Thread A Brother Sewing Machine Xl-5232

(Posted by Thsou 10 years ago)

I Need A Parts And Schematic Manual For Sewing Machine Xl-3200 Brother

(Posted by MANUALS1 10 years ago)