Brother International BAS-416 Support Question

Find answers below for this question about Brother International BAS-416.Need a Brother International BAS-416 manual? We have 13 online manuals for this item!

Question posted by wgripentrog on July 27th, 2021

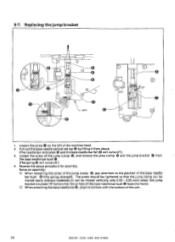

Replacing A Jump Silenoid

Current Answers

Answer #1: Posted by SonuKumar on July 27th, 2021 9:30 AM

https://www.youtube.com/watch?v=oIeMvyZ2GHk

https://www.youtube.com/watch?v=oIeMvyZ2GHk&t=44

https://www.youtube.com/watch?v=oIeMvyZ2GHk&t=51s

https://www.youtue.com/watch?v=oIeMvyZ2GHk&t=84s

=======================

Thank you, Happy to serve!

"Accept my work - Sonu Kumar

========================

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

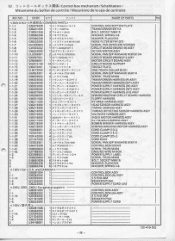

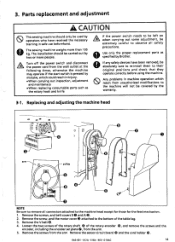

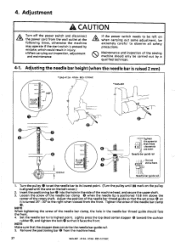

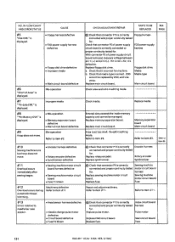

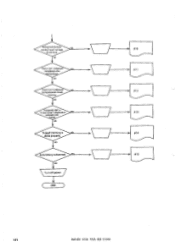

Related Brother International BAS-416 Manual Pages

Similar Questions

what things can I do to get this stop breaking the thread

how to replace bobbin winder assembly on brother HS100 computer sewing machine

The needles on my brother bas416 industrial embroidery machine will not move up and down. How can I ...

I cant get the needles to line up it keeps breaking needles

I Want To Know Above Sewing Machine Price In Indian Rupees,please Anser Me Imediately