Craftsman 30084N - 180 Amp 220 Volt Digital MIG Welder Support and Manuals

Get Help and Manuals for this Craftsman item

View All Support Options Below

Free Craftsman 30084N manuals!

Problems with Craftsman 30084N?

Ask a Question

Free Craftsman 30084N manuals!

Problems with Craftsman 30084N?

Ask a Question

Most Recent Craftsman 30084N Questions

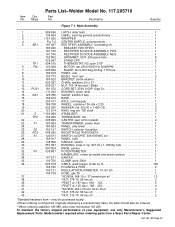

Where Can I Get Parts Since Sears Can't Find Any Without The Model #

30084 does not come up on the sear site. i need the pcb board and sears say they need a model #.

30084 does not come up on the sear site. i need the pcb board and sears say they need a model #.

(Posted by the3arringtons 13 years ago)

Popular Craftsman 30084N Manual Pages

Craftsman 30084N Reviews

We have not received any reviews for Craftsman yet.