Troy-Bilt TB6044 XP Support Question

Find answers below for this question about Troy-Bilt TB6044 XP.Need a Troy-Bilt TB6044 XP manual? We have 2 online manuals for this item!

Current Answers

Answer #1: Posted by khanjee on August 2nd, 2023 1:07 PM

Pipes can suffer from two main faults: leaking or blockage. Probably the first indication you will get of a leak is the smell of petrol wafting into the car - don't delay in finding the problem, as the petrol vapour can be ignited easily.

Twin fuel-pipe system

Twin fuel pipes are checked for leaks in the same way as single ones.Blocked pipes are usually very obvious - the car comes to a halt or suffers from fuel starvation. Thankfully this is now rare because fuel filters are fitted to remove dirt.

Types of pipeThe fuel line typically consists of rigid metal pipes, with flexible rubber or plastic hoses running from the pipes to the tank and the fuel pump , and from the pump to the carburettor . The flexibility of the hoses allows some movement between these different components. On some cars the rigid pipes are made of reinforced plastic rather than metal.

Types of pipe connectionsJubilee clipMetal pipe connection

There are two types of common fuel pipe connections. One is a flexible pipe connection using a Jubilee clip. The other is a metal-to-metal connection. The metal pipe has a tapered flare at the end into which fits an olive. The two pipes are tightened together around the olive, which seals the jointInspectionA fault in the pipes and hoses, or in their connections, is a potential fire hazard, so you should check the system every year.

Disconnect the battery as a safety precaution against any possible sparks . Jack up the car and support it on axle stands. Carefully inspect the pipe along its whole length. Look especially carefully at the joints, checking for dark stains that indicate a leak. Use a spanner to check that all union pipe connections are tight.

Also check each metal pipe for rust - use a wire brush to remove any surface rust on the pipes. If the pipe is badly pitted underneath it should be replaced.

Inspect the flexible hose and connections too. Bend and twist them, looking for any splits. If the pipe has become hardened due to old age or is soft because of oil contamination, it should be replaced. Flexible pipes use several types of securing clip; make sure they are tight and not corroded.

Check the routing of the pipes, they should not run too close to hot engine parts such as the exhaust pipe or manifold . Check the pipe is secure in its clips and isn't chafing on anything.

If you found a pipe or hose that is badly damaged it will need replacing. Before you start work, drain the fuel from the tank into a suitable container and store it safely.

Please Accept my answer by providing you with the best possible solution. Would be more glade.

THANK YOU

Answer #2: Posted by HelpHero on August 3rd, 2023 8:54 PM

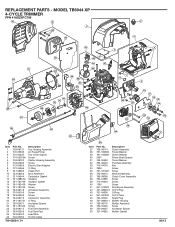

1. Start by removing any remnants of the old fuel lines that may still be attached to the trimmer. Cut them off close to the fuel tank and carburetor using a pair of scissors or wire cutters.

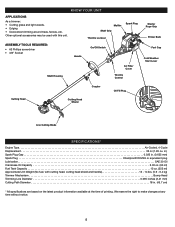

2. Locate the fuel tank. The fuel tank on the TB6044 XP is typically located near the rear handle of the trimmer.

3. Identify the fuel line connections on the fuel tank. There should be two connections: one for the fuel line from the carburetor and one for the return line (if applicable). The connections may be marked with labels like "in" and "out" or "main" and "return."

4. Cut a new piece of fuel line that matches the length of the original fuel line. Ensure the diameter of the replacement fuel line matches the original size as well (usually around 1/4 inch).

5. Slide one end of the fuel line onto the fuel tank connection marked for the fuel line from the carburetor. Ensure it fits snugly and securely onto the connection.

6. Next, locate the carburetor. The carburetor is typically located near the engine and has several fuel line connections.

7. Identify the appropriate fuel line connection on the carburetor for the fuel line. It may be marked with a label or a color code.

8. Cut another piece of fuel line that matches the length of the original line that connected to the carburetor. Slide one end onto the appropriate fuel line connection on the carburetor, ensuring a secure fit.

9. If there is a return line on your TB6044 XP, locate the second fuel line connection on the fuel tank marked for the return line.

10. Cut a new piece of fuel line for the return line and slide one end onto the appropriate fuel line connection on the fuel tank.

11. Finally, trim the excess fuel line if necessary, leaving a clean and tidy installation.

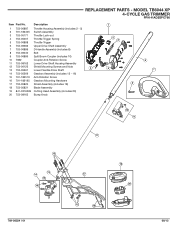

Please note that the exact configuration of the fuel lines may vary slightly between models or variations of the TB6044 XP. Refer to the trimmer's specific user manual or contact Troy-Bilt customer support for detailed instructions and diagrams if needed.

I hope this helps you properly route the fuel lines on your Troy-Bilt TB6044 XP trimmer! If you have any further questions, feel free to ask.

I hope this is helpful? PLEASE "ACCEPT" and mark it "HELPFUL" to complement my little effort. Hope to bring you more detailed answers.

Helphero

Related Troy-Bilt TB6044 XP Manual Pages

Similar Questions

This has me stumped....Old 4 stroke trimmer given to me. All fuel lines broken or gone. Carb...no pr...

the primer has 3 tits, carb has 3 nipples, tank has 2 lines, anyone have a diagram of where each lin...

I think I have fuel lines going to the wrong nipples on the primer bulb. It is a three nipple bulb. ...

I'm having trouble knowing where to correctly place the 3 fuel lines any help?