Stihl BR 550 Support Question

Find answers below for this question about Stihl BR 550.Need a Stihl BR 550 manual? We have 3 online manuals for this item!

Question posted by melvinfaulkner17 on December 1st, 2019

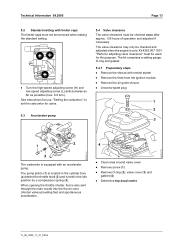

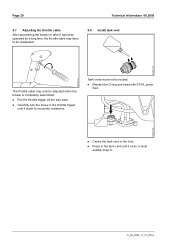

Valve Adjustment

Current Answers

Answer #1: Posted by hzplj9 on December 1st, 2019 12:25 PM

https://www.manualslib.com/manual/1193020/Stihl-Br-700.html#product-BR%20550

Good Luck.

Answer #2: Posted by salvagedrover on October 29th, 2020 10:38 AM

On a side note, I feel this series of machines (STIHL 4Mix) gets a bad rap for a lack of simple preventative maintenance. Someone who wouldn't think twice about changing the oil in their car completely disinterested in maintaining OPE that he spends hundreds, sometimes thousands of dollars on. It's a tool to be used to complete a project to either save or make money, so why not maintain your machines to continue with that very mindset? Adjusting valves and replacing fuel lines are very simple, inexpensive, and very frequenty OVERLOOKED steps anyone can perform with a little guidance, to ensure long life and productivity from any piece of OPE, not only STIHL but any 2-cycle or 4-cycle machine. Good luck with your valve adjustment!

Related Stihl BR 550 Manual Pages

Similar Questions

it won't fire up