Ryobi P320 Support Question

Find answers below for this question about Ryobi P320.Need a Ryobi P320 manual? We have 2 online manuals for this item!

Question posted by hamadcid on June 29th, 2017

My Ryobi P320's Stricker Pin Does Not Go Back, I Have To Push It Back

Please let me know what is the problem and its solutionRegards

Current Answers

Answer #1: Posted by hzplj9 on June 29th, 2017 3:11 PM

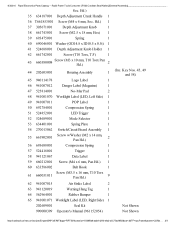

If you refer to the diagram it may be possible for you to identify the problem. It could be that you have a brad jammed inside or the spring that enables the return is broken.

https://manuals.ttigroupna.com/system/files/9363/original/P320_399_r_04.pdf?2017

From the same link you can obtain a user guide as well.

Related Ryobi P320 Manual Pages

Similar Questions

Magazine Support Failure On Ryobi P320 Brad Nailer Airstrike

my magazine support shot off of my Ryobi brad nailer when trying to load why did this happen

my magazine support shot off of my Ryobi brad nailer when trying to load why did this happen

(Posted by Ianlowe76 3 years ago)

Where Can I Find The D Handle F

it says is discontinued but I really need this part to fix my tool please let me know how I can find...

it says is discontinued but I really need this part to fix my tool please let me know how I can find...

(Posted by Paogabriela1989 3 years ago)

Ryobi P320 Battery Nailer

hi, can anyone help to identify the values of the 2 shunt resistors surrounding the thermal cut out ...

hi, can anyone help to identify the values of the 2 shunt resistors surrounding the thermal cut out ...

(Posted by smhjpdj 5 years ago)

I Have To Remove Arm Support Bracket To Replace It After A Falling Accident

dear sirs I removed two little nuts and am stocked with lock pins , so what tool do you use to remov...

dear sirs I removed two little nuts and am stocked with lock pins , so what tool do you use to remov...

(Posted by thguenand 8 years ago)

My P320 Just Flashes When I Put A Battery In

my p320 just flash when you put a fully charged battery in

my p320 just flash when you put a fully charged battery in

(Posted by nolimitsbob 8 years ago)