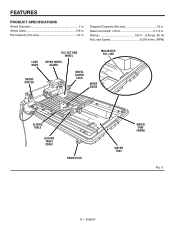

Ridgid R4030 Support Question

Find answers below for this question about Ridgid R4030.Need a Ridgid R4030 manual? We have 1 online manual for this item!

Question posted by Uameye on June 29th, 2016

Noise Level.

R4030 Noise when water is introduced when there is a load or no load, otherwise acceptable noise level.

Current Answers

Answer #1: Posted by TommyKervz on July 2nd, 2016 6:32 AM

If you feel that there is a problem with your tile saw, it can be checked by your closest authorized RIDGID service provider, found in the service center locator link below, to see if there is some type of problem with the unit that is causing the motor to be unusually louder than normal or the rough cuts you are experiencing. If the tile saw was purchased as new, not factory reconditioned, it does carry a three year warranty based on your proof of purchase, under which any warranty related issue found with the tile saw can be covered and corrected.

https://www.ridgid.com/us/en/servic...

https://www.ridgid.com/us/en/servic...

Related Ridgid R4030 Manual Pages

Similar Questions

Kj 3100 Water Filter

my water filter plug keeps popping of when I put the pulse on my kJ-3100

my water filter plug keeps popping of when I put the pulse on my kJ-3100

(Posted by fodorplumbing 2 years ago)

Rp-210 Crimper Tool

how can we order a replacement motor for the tool. the end has come off part way and the tool in una...

how can we order a replacement motor for the tool. the end has come off part way and the tool in una...

(Posted by webb97907 8 years ago)