Ridgid R350RHE Support Question

Find answers below for this question about Ridgid R350RHE.Need a Ridgid R350RHE manual? We have 2 online manuals for this item!

Question posted by heimlichelectric on August 28th, 2021

I Have Air Coming Out Of The Top Of My R350rhe.doesnt Work

Current Answers

Answer #1: Posted by SonuKumar on August 28th, 2021 10:27 PM

https://www.youtube.com/watch?v=dqaSt5x7Ync&t=58s

https://www.youtube.com/watch?v=dqaSt5x7Ync&t=117s

https://www.youtube.com/watch?v=dqaSt5x7Ync&t=277s

https://www.youtube.com/watch?v=dqaSt5x7Ync&t=330s

https://www.youtube.com/watch?v=dqaSt5x7Ync&t=344s

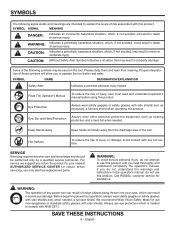

Why is my nail gun just shoots air?

If you try to fire a pneumatic nail gun or stapler, but only hear air leaking when engaging the trigger, it's likely that your tool's "O-Ring" is not sealing properly. ... Simply stretch the "O-Ring" on the firing valve and apply grease. This should take care of the issue - helping your air tool run properly.

https://www.finepowertools.com/nailers/nail-gun-not-shooting/

https://www.fixya.com/search/p1022441-ridgid_full_round_head_framing_nailer_3/air_leaking

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Ridgid R350RHE Manual Pages

Similar Questions

gun was working fine then stopped shooting nails the gun is not jammed the slide won't go all the wa...

Upper plastic bumper disintegrated, Part HM079005004079 is discontinued and no other replacement par...

I can't fine in the operators manual for my r350che that part that tells me how to adj. the pres. On...