Ridgid EB4424 Support Question

Find answers below for this question about Ridgid EB4424.Need a Ridgid EB4424 manual? We have 1 online manual for this item!

Question posted by ferrellandcelest on September 11th, 2021

Spindle Will Not Move Began To Smoke

anything I can do or take to s

Current Answers

Answer #1: Posted by SonuKumar on September 11th, 2021 11:34 PM

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

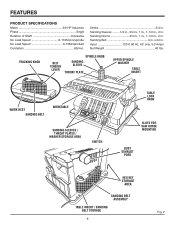

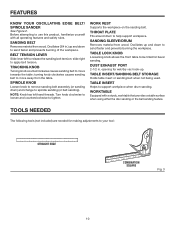

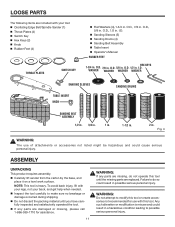

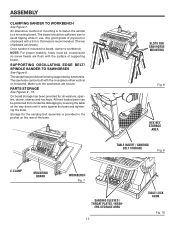

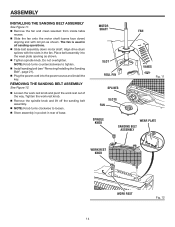

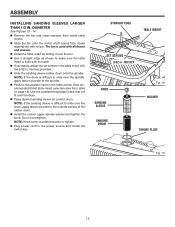

Related Ridgid EB4424 Manual Pages

Similar Questions

I Need The Part Number For The Motor.

please supply part number for new motor. Mine is smoked. Thank you

please supply part number for new motor. Mine is smoked. Thank you

(Posted by Jeffreyintenzo 6 months ago)

Rp-210 Crimper Tool

how can we order a replacement motor for the tool. the end has come off part way and the tool in una...

how can we order a replacement motor for the tool. the end has come off part way and the tool in una...

(Posted by webb97907 8 years ago)

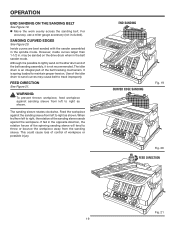

Rigid Spindle Sander Manual Changing The Belt To A Simple Spindle Sander.

Can't seem to locate my manual and want to change the belt configuration to a simple single spindle ...

Can't seem to locate my manual and want to change the belt configuration to a simple single spindle ...

(Posted by evace109 8 years ago)

Where Can I Purchase A Spindle Knob For The Rigid Belt Sander For Eb 44242

(Posted by johncrausen 10 years ago)

Where Can I Buy Sanding Spindals For Me Ridgid Eb4424

(Posted by DAVEAMICO 10 years ago)