Pfaff synchromatic 1229 Support Question

Find answers below for this question about Pfaff synchromatic 1229.Need a Pfaff synchromatic 1229 manual? We have 1 online manual for this item!

Question posted by mlrodgers on March 31st, 2023

Pfaff 1229 Needle Won't Lower And Handwheel Won't Turn.

Current Answers

Answer #1: Posted by SonuKumar on March 31st, 2023 10:58 PM

- Check the machine for any obstructions: Before doing anything else, check your sewing machine thoroughly for any obstructions that might be preventing the needle from moving or the handwheel from turning. Look for things like tangled thread or broken needles.

- Check the presser foot lever: Make sure the presser foot lever is in the correct position. If the presser foot is in the down position, it can prevent the needle from moving.

- Check the bobbin winder: Make sure the bobbin winder is not engaged. If the bobbin winder is engaged, it can prevent the needle from moving and the handwheel from turning.

- Check the machine's settings: Make sure that the machine is set to the correct stitch length and tension settings. If the settings are too tight, it can prevent the needle from moving and the handwheel from turning.

- Check the machine's lubrication: Make sure that your machine is properly lubricated. A lack of lubrication can cause the machine to seize up and prevent the needle from moving and the handwheel from turning.

If none of these steps work, it's possible that there is a more serious issue with your machine. In that case, you may need to take it to a professional for repair.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Answer #2: Posted by Odin on March 31st, 2023 8:54 AM

If the issue persists or if you require further advice, you may want to consult the company: use the contact information at https://www.contacthelp.com/pfaff.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Answer #3: Posted by shlokuprit on March 31st, 2023 9:11 AM

1. Check the bobbin winder - make sure it is not engaged, as this can prevent the needle from moving.

2. Check for tangled thread or debris - open up the bobbin area and the needle plate and look for any tangled thread or debris that may be causing the needle and handwheel to jam.

3. Check the presser foot - make sure the presser foot is not engaged, as this can also prevent the needle from moving.

4. Check the belt - the belt that drives the machine may have come loose or broken, which can cause the needle and handwheel to stop working.

5. Lubricate the machine - if none of the above steps work, it may be a lubrication issue. Try oiling the machine according to the manufacturer's instructions.

NOTE: If none of these steps solve the issue, it may be best to take your Pfaff 1229 to a professional repair technician for further diagnosis and repair.

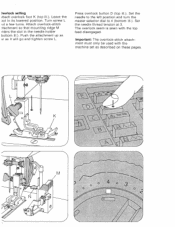

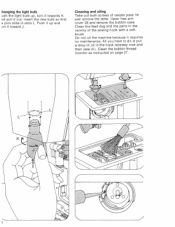

Related Pfaff synchromatic 1229 Manual Pages

Similar Questions

Unfortunately my overlock foot broke. Is it possible to buy a replacement?

When I lower the presser bar lifter, the rod holding the foot takes a long time to decend and then d...

My Pfaff Synchrotronic 1229 has a problem. It is very hard to rotate the master selector dial and th...