Pfaff hobbylock 784 Support Question

Find answers below for this question about Pfaff hobbylock 784.Need a Pfaff hobbylock 784 manual? We have 1 online manual for this item!

Current Answers

Answer #1: Posted by Odin on March 30th, 2019 6:24 AM

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

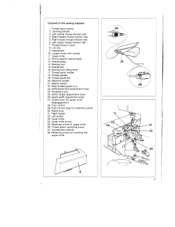

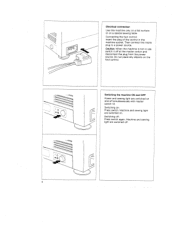

Related Pfaff hobbylock 784 Manual Pages

Similar Questions

Edge Guide - Pfaff Select 1540 Sewing Machine

How does the Edge Guide work for the Pfaff Select 1540 sewing machine?

How does the Edge Guide work for the Pfaff Select 1540 sewing machine?

(Posted by jesjames 2 years ago)

Hobbylock 784

I lost the pedal of my hobbylock 784, How can I rich a new one?

I lost the pedal of my hobbylock 784, How can I rich a new one?

(Posted by shelly2004 2 years ago)

Machine Doesn't Turn Freely

The sewing mechanism doesn't turn freely, is there a service manual that could help me open the mach...

The sewing mechanism doesn't turn freely, is there a service manual that could help me open the mach...

(Posted by semalmquist 6 years ago)

Pfaff 259 Sewing Machine Won't Run With Foot Petal

I have a pfaff 259. When I push on the foot petal the motor runs but the machine itself doesn't run....

I have a pfaff 259. When I push on the foot petal the motor runs but the machine itself doesn't run....

(Posted by Aemazing 8 years ago)