Pfaff hobbylock 784 Support Question

Find answers below for this question about Pfaff hobbylock 784.Need a Pfaff hobbylock 784 manual? We have 1 online manual for this item!

Question posted by rgzrngrace on July 30th, 2015

Yellow Tension Thread

Thread always breaks in the yellow tension.

Current Answers

There are currently no answers that have been posted for this question.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Related Pfaff hobbylock 784 Manual Pages

Owner's Manual - Page 4

... the upper knife Changing the lower knife Oiling the machine Sewing problems and their removal Accessories Thread spool net/thread unreeling disc Specifications Contents of the upper knite Setting the standard thread tensions Correcting the thread tensions 3-thread overedge seam Thread chart Adjusting the stitch length on hobbylock 784 and 786 Adjusting the differential feed (hobbyfock 786...

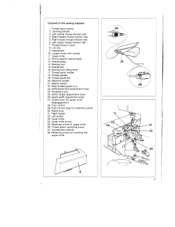

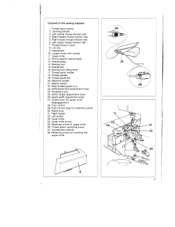

Owner's Manual - Page 5

...Controls of the sewing machine

1 Thread spool stand 2 Carrying handle 3 Left needle thread tension dial 4 Right needle thread tension dial 5 Right looper thread tension dial 6 Left looper thread tension dial 7 Thread tension cover 8 Lint box 9 Handwheel 10 Looper cover with recess 11 Upper knife 12 Work support (swivel-type) 13 Needle plate 14 Sewing foot 15 Needle bar 16 Sewing foot lifting lever...

Owner's Manual - Page 6

... on the foot control. Switching off at the master switch and

disconnect the plug from the power source. Machine and sewing light are switched off simultaneously with master

switch 12.

Electrical connection Use this machine only on a flat surface or on . Connecting the foot control: Insert the plug of the control in use...

Owner's Manual - Page 7

... Hobbylock is 15 watts.

Position

= Half speed

Position +4 = Full speed

Notes on the foot control. Electronic foot control

Maximum speed can be disconnected from the power source. C) The maximum approved wattage of the light bulb is regulated as follows:

The more you press the foot control down, the faster the machine will sew...

Owner's Manual - Page 9

... cover, push it down again.

7 This diagram shows the different threading paths by different colors (see Fig.

Then thread the tensions in the following sequence: 1. C). I

n E1

H

Opening and closing looper cover and work support

Push looper cover fully to the machine behind the carrying handle

The machine must be pushed down . First pull the respective...

Owner's Manual - Page 10

...is sewn with two needle threads and two looper threads. Threading the right looper: Thread the right looper in sequence 1 to obtain perfect sewing results, the thread must be pulled between the tension discs when threading the tensions.

If'

5,

/2 /

8

1

5

H

6

8

Important: In order to 9 and pull approximately 10 cm (4") of thread through the looper eye (the thread path is marked red...

Owner's Manual - Page 12

... knots are about 10 cm of thread through the

respective needle eyes.

At point 5 the thread must be pulled behind the thread retainer. Tie the threads still in the machine and the new threads together. In the left-hand illustration the threading path is shown from the blue tension (1) up to the thread spool. Thread spool change on page 7. Cut...

Owner's Manual - Page 13

the lint box, use the

I -J

/

/

Inserting the lint box:

downwards the cover.

Then push the bottom of the box against the machine. I

Seam allowance

If the cutting is guided along below

1

I

After threading the machine, push handle

2 down, and close work support 12 and

- looper cover 10.

Owner's Manual - Page 14

... with your left hand while turning hand wheel with your right

hand in the illustration. Lay the threads back under the sewing foot. Sewing test After threading, a sewing test test should be made. Raise sewing foot lever 16, as shown in the direction indicated by the

arrow on the wheel. Insert test fabric up to the...

Owner's Manual - Page 16

... thick fabrics or workpieces with different thicknesses:

On this machine, all kinds of fabric from extremely thin to pull the thread chain into the seam. Securing the seam:

Knot the thread chain.

Note:

When sewing thin or medium fabrics, the screw of the upper knife must be processed.

By tightening the screw, axial movement...

Owner's Manual - Page 18

... is increased. J

The right needle thread B is too tight (yellow thread tension) or the right

looper thread C too loose (red thread tension).

16 Top side

DC Reverse side

The right looper thread C is too tight (red thread tension> or the left needle thread A is too loose (blue thread tension). Correcting the thread tensions

When the thread tension is turned in (-) direction it is

decreased...

Owner's Manual - Page 20

...Silk Synthetic thread

No. 40-60 No. 40-60 No. 70-140

Polyester thread No. 120-140 Mercerized thread

(bulk thread)

Stitch length 2.0 to 4.0 mm

2.0 to 4.0 mm

2.0 to 5.0 mm (784) 2.0 to 4.0 mm (786)

2.0 to 5.0 mm (784) 2.0 ...length on the hobbylock 784 without differential feed

Open work support 12. Setting the stitch length on the hobbylock 786 with differential feed

Open work support 12.

Owner's Manual - Page 21

... possible stroke The differential feed can be employed to process (see table on the hobbylock 786 The differential feed prevents inter-ply shift. The following variants can be set ...processed. Owing to that very good sewing results are possible: Setting 0.5 = Short stroke of front feed

dog, long stroke of 0.5 when medium to 2, also during sewing. Note: The following settings at ...

Owner's Manual - Page 23

...fully to the right, hold it, and turn it may be necessary to re-adjust the thread tension.

21

Set the upper knife at its basic position again and close the looper cover. If ...necessary, loosen screw 38 for blocking the upper knife, see page 14,

Sew a test seam. Now the upper knife is

marked with adjusting knob 26. * 0

Disengaging the upper knife

...

Owner's Manual - Page 25

....) with the pins in retainers A of arrow) and remove it fully to remove dust and lint from between the tensions. Replace the thread tension cover by engageing the tabs of the sewing light is situated. I

'\

H

Changing the light bulb: Pull out the mains plug. Cleaning the thread tensions: Pull thread tension cover 7 with the accessories to the left.

Owner's Manual - Page 27

....

"N" approx. left looper, yellow path needle thread, green path

For threading of the sewing machine:

Needle: Sewing foot: Seam width: Stitch length:

Thread:

reffperrnooomgmmlyaoegv31see..t00elrreottooflttlhe42rnd..e00eahedm(edsmlmh1eo2f0r(ot-does1ttp4i"et0cRnhf"doirlneggnrgeotehnn),mraetderiaanld)

yellow

thread

tensions

Threading path:

polyester thread

1. "N"

flat edge, Fig...

Owner's Manual - Page 28

... is at its highest position.

Changing the knives

are used on these machines: System 130/705 H (75-90)

Although the correct needle size depends on the material and the thread size used, we recommend needle size 75-90. Lower the sewing foot. PKunlilvoesut the mains plug.

Remove the needle by pulling it will...

Owner's Manual - Page 32

... correctly (page 26). Puckered seams 30

Thread tension too tight.

Problem

______

Needle breakage

Cause

Needle bent or point damaged. Thread breakage

Incorrectly threaded.

Thread correctly (pages 7-10).

Incorrect needle used . Sewing problems and solutions

These machines have been developed for light materials) (pages 15, 16). Sewing problems of the kind described below...

Owner's Manual - Page 33

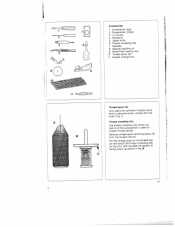

...

5 Upper knife 6 Thread unreeling disc

7 Needles 8 Sewing machine oil

I

9 Rolled hem sewing foot

10 Thread spool net

11 Needle change tool

I

item 6 of it, with rounded-off section C facing down, as

I

Thread spool net

Very useful for

smaller thread spools. Remove thread spool centering piece 36

from the thread reel pin.

/

Put the thread spooi on the thread reel pin and...

Owner's Manual - Page 34

... Seam width Stitch length

Sewing foot Lubrication Sewing foot height Needle system Number of threads Dimensions Weight

Contents of cardboard box

1 machine with motor 1 foot control 1 instruction manual/guarantee certificate 1 lint box 1 thread spool stand 4 thread spool stand bars 1 thread guide 1 machine cover

1.300 stitches/mm. 3-7.2mm 1 -4 mm (HL-786) 1 -5 mm (HL-784) Hinged Manual 5mm 130...

Similar Questions

Edge Guide - Pfaff Select 1540 Sewing Machine

How does the Edge Guide work for the Pfaff Select 1540 sewing machine?

How does the Edge Guide work for the Pfaff Select 1540 sewing machine?

(Posted by jesjames 2 years ago)

Hobbylock 784

I lost the pedal of my hobbylock 784, How can I rich a new one?

I lost the pedal of my hobbylock 784, How can I rich a new one?

(Posted by shelly2004 2 years ago)

How To Thread The Hobbylock784

I have bought a used hobbylock784 784 however there is no manual with it.I do not know the order of ...

I have bought a used hobbylock784 784 however there is no manual with it.I do not know the order of ...

(Posted by Tene020750 6 years ago)

Pfaff C1100 Pro Sewing Machine Instruction

Can you please direct me to "easy" to understand instruction on how to "thread" my Pfaff C1100 Pro s...

Can you please direct me to "easy" to understand instruction on how to "thread" my Pfaff C1100 Pro s...

(Posted by magicfeathers55 10 years ago)