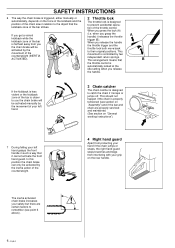

Husqvarna 3120 XP Support Question

Find answers below for this question about Husqvarna 3120 XP.Need a Husqvarna 3120 XP manual? We have 3 online manuals for this item!

Question posted by husqvarnahania on February 19th, 2015

Throttle Spring?

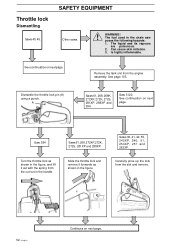

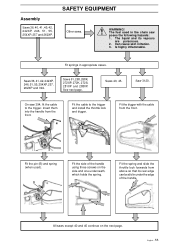

hi,how i put the throttle spring of husqvarna 3120xp?

Current Answers

Answer #1: Posted by waelsaidani1 on February 19th, 2015 9:36 AM

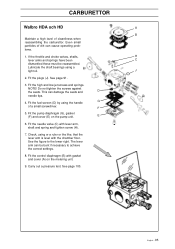

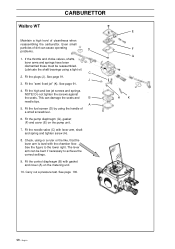

Related Husqvarna 3120 XP Manual Pages

Similar Questions

How To Replace The Throttle Recoil Spring On Husqvarna 326ls

(Posted by Anonymous-168781 2 years ago)

I Have Ahusqvarna 323l 2005. I Need To Replace The Spring In The Throttle Handle

i need replaceing the spring in the throttle handle. i need a repair manual that shows how to in a 2...

i need replaceing the spring in the throttle handle. i need a repair manual that shows how to in a 2...

(Posted by cgwinn2223 3 years ago)

Proper Positioning Of Throttle Spring On Husqvarna 122c

What what is the proper installation position for throttle spring

What what is the proper installation position for throttle spring

(Posted by dancozac2 3 years ago)

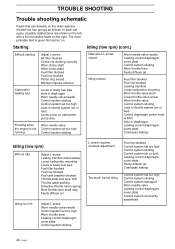

Trouble Setting The Throttle Spring On Gas Chainsaw Husqvarna 365

i was replacing d gas line and somehow the throttle stop functioning so i took it apart and now i do...

i was replacing d gas line and somehow the throttle stop functioning so i took it apart and now i do...

(Posted by figueroajoanne 9 years ago)

Throttle Handle 336fr (inside)

i want to assemble the throttle handle. Where do "springs" go inside? Thanks!

i want to assemble the throttle handle. Where do "springs" go inside? Thanks!

(Posted by michelnolet 9 years ago)