Hitachi NT65MA3 Support Question

Find answers below for this question about Hitachi NT65MA3 - 2-1/2 Angled Finish Nailer.Need a Hitachi NT65MA3 manual? We have 1 online manual for this item!

Question posted by jph99980 on May 22nd, 2012

I Have A Nv 50ap3. Can I Adjust The Depth Of The Nail So I Can Use Only Nails?

I don't want to use caps but the nails are not driven all the way down. Is there a way to adjust for the depth of the cap.

Current Answers

There are currently no answers that have been posted for this question.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Related Hitachi NT65MA3 Manual Pages

Instruction Manual - Page 3

... PRINCIPLE 8 8-1. Interchangeability ...10 8-3. Operation Principle ...11

9. General Precautions in Disassembly and Reassembly 19 10-2. Disassembly and Reassembly of Nail Use ...4 5-5. SPECIFICATIONS ...2 5-1. Examples of the Cap and the Magazine Section 26

11. Optional Accessories ...5

6. Warning Label ...7 7-3. TROUBLESHOOTING GUIDE ...14 9-1. Disassembly and Reassembly of...

Instruction Manual - Page 4

Aggressive design similar to -use clogged nail release mechanism

"Single actuation/contact actuation" selector

--- 1 --- MARKETING OBJECTIVE The new Model NT 65MA3 finish nailer is a minor-changed version of cleaning chips and sawdust thanks to the blow nozzle

Grip rubber

Simple drivedepth adjusting

mechanism

Easy-to the Model NR 90AD Light weight (1.9 kg)

3. Primary differences from ...

Instruction Manual - Page 5

...(Length x Height x Width) (13-1/2" x 12" x 3")

Nail feed system Nail capacity

Spiral spring 100 nails

Air consumption

Air inlet Packaging

1.20 ltr/cycle at 6.9 bar (1.20...cap (Code No. 881751) 1

Optional accessories

Full sequential actuation mechanism kit

(Code No. 884320)

(Sequential trip mechanism kit)

Pneumatic tool lubricant (30 cc (1 oz) oil feeder) (Code No. 877153)

Pneumatic tool...

Instruction Manual - Page 6

... trigger; If the trigger is held back, a nail will not be driven each time the pushing lever is pressed against the wood to be performed. FULL SEQUENTIAL ACTUATION MECHANISM: First, press the pushing lever against the wood;

next, pull the trigger to drive the nail. Use SINGLE ACTUATION MECHANISM (SINGLE SEQUENTIAL ACTUATION MECHANISM) or...

Instruction Manual - Page 7

... Nail Use A: Crown molding

Fig. 1 Dimensions of nails

B: Base molding

Examples of uses for the nails shown in 5-2 for installing finish materials, or molding as specified in Fig. 2. Applicable nails are shown in circles A and B. CAUTION: Ensure that nails are as shown in Fig. 1. Fig. 2 Examples of nails and

subsequent damage to the nailer.

15-gauge finish nail (collating angle...

Instruction Manual - Page 8

...Required nailing energy

Nailer output energy

Plywood (12 mm (.472") thick) x 6

P

S NT 65MA NT 65MA2 NT 65MA3

NT65MA3

Fig. 3 Required nailing energy and nailer output ...nailer to be fully driven. Air pressure which exceeds the intersecting point between the nailer output energy and the required nailing energy for correct use it. For example, when driving a nail of wood and nail the nailer...

Instruction Manual - Page 9

... to 8.5 kgf/cm2 )

(70 to 120 psi)

S

4.9 to 8.3 bar (5 to 8.5 kgf/cm2 )

(70 to 2-1/2") Handle grip

Collating angle

Applicable nails

Dia.

Length

Rubber

34û

2.4 mm to 3.0 mm (.095" to .12")

32 mm to 65 mm (1-1/4" to 2-1/2")

Rubber

34û

... hand

by hand

Driving depth adjustment mechanism

Horizontal dial

Horizontal dial

Horizontal dial

Horizontal dial

Vertical slide

--- 6 ---

Instruction Manual - Page 11

....302 Power-operated hand tools Portable, Compressed-Air-Actuated, Fastener Driving Tools-Safety Requirements for applicable ...section. 7-3. Related Laws and Regulations As nailers and staplers are used as much as that the customer is ...Cap (A): Newly designed

Control valve section Common to the Model NT 65MA2 Driving section and magazine section Almost common to instantaneously drive nails...

Instruction Manual - Page 12

... Lever [34] Guide Plate (A) [33] Blade Guide [37]

Pushing Lever (A) [40]

Blow nozzle section

Knob [24]

Cap (A) [49] Body Ass'y [30]

Control valve section

Air Plug NPT 1/4 [51]

Trigger (A) [53]

Magazine Cover [76]

Nail Stopper [81]

Nail Rail [79]

Magazine [82]

Nail Feeder (B) [80]

Magazine section

Nail Feeder (A) [74]

Fig. 4 Construction

Output section

Driving section

--- 9 ---

Instruction Manual - Page 14

... the Piston [15] downward to seal Head Valve (A) [10] Return air chamber

and Cylinder [11].

(2) When nailing: (Fig. 5 and Fig. 6)

1) When Pushing Lever (A) [40] and Trigger (A) [53]

are operated together... (A) [68] is

Pushing Lever (A) [40]

pushed upward, the compressed air in the valve

Nail

piston lower chamber is fed through the air passage.

3) When the air pressure applied on the ...

Instruction Manual - Page 16

... while holding Trigger (A) [53] depressed. The Piston [15] then returns

Accumulator

fully upward. Contact actuation mechanism (Switching device:

downward position):

1) Immediately after the first nail is driven, the control valve should be accomplished by turning the switching device

(Change Knob [57]). Compressed air then flows into the valve

Fig. 9 Single actuation mechanism...

Instruction Manual - Page 17

... or damaged). Remedy

Use specified nails. Replace the part.... dust, or worn).

Oil Nail rail Adjust the air pressure to 4.9 to...Nail groove in the back position after loading nails and check if the nail feeder operates smoothly. Adhesive fragments and wood chips are on the magazine, nail feeder or nail rail.

Remove the abnormal nails and load the nailer with specified genuine nails...

Instruction Manual - Page 18

... valve bushing (B) is incorrectly set. O-ring or sliding surface is worn or needs lubrication.

2) Nails are used because the material is beyond its applicable range.

Workpiece is bent even when driven into the workpiece completely: the heads cannot be used . Adjuster is abnormal (seized or damaged). Workpiece is not raised too high.

Disassemble the control...

Instruction Manual - Page 19

... spring. Check each part for abnormalities (worn, damaged, deformed, etc.)

The position of the blow nozzle. Replace the part. Problem

Possible cause ( : most-common cause)

4) Nails jam. (continued)

< Driver blade is not returned completely > See item "1) Output section: piston, driver blade, etc."

5) Single actuation mechanism is worn.

O-ring in plunger (A) is...

Instruction Manual - Page 22

...item numbers in the descriptions below . Socket Hd. Socket Hd. Use the conventional grip tape for each part

Bolt and screw Hex.... the nailer (with your finger released from the trigger) to exhaust all the compressed air and remove all nails.

10...cannot be mounted without the specifically designed jig. Oil required: Hitachi pneumatic tool lubricant 30 cc (1 oz) Oil feeder (Code No. 877153) 120...

Instruction Manual - Page 28

...bar wrench (5 mm). can be removed. Now, the Adjuster [38] can be removed. Bolt M6 x 30 [32]

Guide Plate (A) [33]

Pushing Lever Guide [58]

[Tools required] Hex. Bolt (W/Flange) M5 x 20 [78... careful not to ADJUSTING THE NAILING DEPTH on

page 21 in the Instruction Manual) so that

Roll Pin D3 x 20 [43]

Adjuster [38]

Pushing Lever (A) [40] can be

removed from the Adjuster [38] with ...

Instruction Manual - Page 30

... the magazine section

(a) Disassembly Remove the Hex. Bolt (W/Flange) M5 x 20 [78]

Nail Rail [79]

Nail Stopper [81]

Nylon Nut M5 [44]

Ribbon Spring [72]

Magazine [82]

Roll Pin D2.5 x 20 (Stainless) [73]

Nail Feeder (A) [74]

Nail Feeder (B) [80]

Pushing Spring [75]

[Tools required] Phillips screwdriver Hex. Pull out the Roll Pin D2.5 x 20 (Stainless...

Instruction Manual - Page 31

...sequential actuation)" (see 5-2). Perform nailing operation and check that Pushing Levers (A) [40] and (B) [36], Trigger (A) [53], Plunger (A) [68], Change Knob [57] and Adjuster [38] operate smoothly without connecting ... to 4.5 kgf/cm2 (63 psi) and load nails in the Magazine [82] and the Blade Guide [37].

(1) Check that nails are properly driven (no air leakage and the Model NT 65MA3 does...

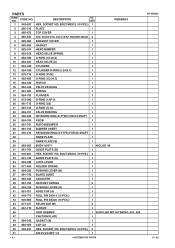

Instruction Manual - Page 34

...894 HOLDER SPRING

1

36 884-326 PUSHING LEVER (B)

1

37 881-742 BLADE GUIDE

1

38 884-325 ADJUSTER

1

39 881-765 RATCHET SPRING

2

40 884-324 PUSHING LEVER (A)

1

41 881-751 NOSE CAP (A)

1

42 949-770 ROLL PIN D4X14 (10 PCS.)

1

43 949-685 ROLL PIN D3X20 (10 PCS...PLATE

1

29

NAME PLATE (B)

1

30 885-963 BODY ASS'Y

1 INCLUD. 46

31 881-764 GUIDE PLATE (B)

1

32 949-661 HEX. USED

HEX.

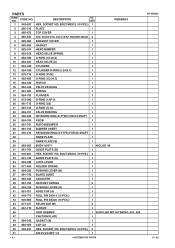

Instruction Manual - Page 35

...NAIL RAIL

1

80 881-744 NAIL FEEDER (B)

1

81 881-766 NAIL STOPPER

1

82 885-962 MAGAZINE

1

REMARKS

NT 65MA3

9 -- 06

* ALTERNATIVE PARTS

--- 3 --- PARTS

ITEM NO. SOCKET HD.

CODE NO.

52

DESCRIPTION HITACHI LABEL

NO. USED...

1

73 881-767 ROLL PIN D2.5X20 (STAINLESS)

1

74 881-746 NAIL FEEDER (A)

1

75 880-321 PUSHING SPRING

1

76 881-752 MAGAZINE COVER

1

77 885-997 MACHINE ...

Similar Questions

Nt65ga Will Not Fire

NT65GA Does not fire when trigger is pulled. Battery has full charge.

NT65GA Does not fire when trigger is pulled. Battery has full charge.

(Posted by dmcgeeoo6 7 years ago)

Wear To Get Nails For A Vh650

wear to buy nails for vh650 1 1/4" ring

wear to buy nails for vh650 1 1/4" ring

(Posted by Fen12153 7 years ago)

What Nails To Use With Hitachi Nr90ad

(Posted by Nitrsamedm 9 years ago)

What Kinds Of Nails Can You Use In A Hitachi Nr90ae

(Posted by Gizhelpow 10 years ago)

Can I Use Rounded Head Nails With This Gun?

(Posted by Bdff 11 years ago)