Dewalt DWE7491RS Support Question

Find answers below for this question about Dewalt DWE7491RS.Need a Dewalt DWE7491RS manual? We have 2 online manuals for this item!

Question posted by amitelazar1 on December 22nd, 2015

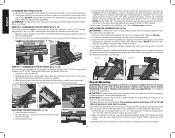

Problem With The Rip Fence Latch

after using my new dwe 7491 rs for only few hours the rip fence latch is almost completely stuck, turning the fine adjust knob requires substantial effort . is this a common problem with this model? what should i do/

Current Answers

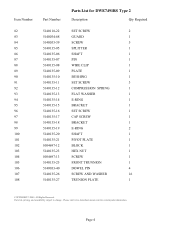

Related Dewalt DWE7491RS Manual Pages

Similar Questions

The Rack And Pinion Fence Knob Is Extremely Difficult To Turn.

(Posted by mystme 9 years ago)

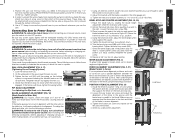

My Fence Adjustment Knob Has Become Very Hard To Turn.

i blow the tracks out with air helps sometimes. worked easily when new. problem comes and goes.

i blow the tracks out with air helps sometimes. worked easily when new. problem comes and goes.

(Posted by alandavidfrey 9 years ago)

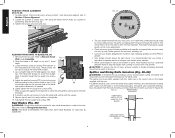

Rip Fence Lock

How do you adjust the locking system for the rip fence?

How do you adjust the locking system for the rip fence?

(Posted by kawtool 9 years ago)