Brother International BAS-423 Support Question

Find answers below for this question about Brother International BAS-423.Need a Brother International BAS-423 manual? We have 11 online manuals for this item!

Question posted by ranmor on August 28th, 2013

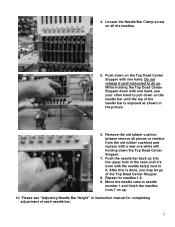

Bas423 Brother Needle Case Error And Grinding For Needle Position?

Brother bas423 grinding noise from needle case motor, after turning it on! I removed the motor no problem with sliding 3heads back and forth motor tight??

Current Answers

Related Brother International BAS-423 Manual Pages

Similar Questions

How To Position Needle Bar Directly Over Needle Plate Mine Is A Little Off To Th

Brother be a S4 23 how to position needle directly over needle plate I am getting the read needle er...

Brother be a S4 23 how to position needle directly over needle plate I am getting the read needle er...

(Posted by Skysembroidery 7 years ago)

Brother Bas 423 Control Panel

I am desperately trying to find a control panel for a brother 423 embroidery machine. Do you know wh...

I am desperately trying to find a control panel for a brother 423 embroidery machine. Do you know wh...

(Posted by carla85579 9 years ago)

Auto Threader On Brother Sewing Machine Ce 8080prw

my new brother sewing machine auto threader does not work.have changed needle position and needles s...

my new brother sewing machine auto threader does not work.have changed needle position and needles s...

(Posted by curtisbuchanan48 10 years ago)

How To Change Needle Brother Sewing Machine Ce 5500 Prw

i lost my manual and do not know how to change the needle for a brother sewing machine CE 5500 PRW. ...

i lost my manual and do not know how to change the needle for a brother sewing machine CE 5500 PRW. ...

(Posted by giomariagina 11 years ago)

Brother 423 Needle Bar

What causes it to go back down after a trim which will make it get caught in the preeser foot if you...

What causes it to go back down after a trim which will make it get caught in the preeser foot if you...

(Posted by zapsprint 11 years ago)