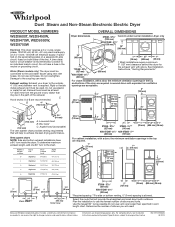

Whirlpool WED9550WL Support Question

Find answers below for this question about Whirlpool WED9550WL.Need a Whirlpool WED9550WL manual? We have 5 online manuals for this item!

Question posted by eagleneely on September 18th, 2013

Can My Dryer Function Normaly If I Don't Connect The Water Line

i have a whirlpool gas dryer with steam function and was wondering if it would function normal if i dont connect a water line to it

Current Answers

Related Whirlpool WED9550WL Manual Pages

Whirlpool Knowledge Base Results

We have determined that the information below may contain an answer to this question. If you find an answer, please remember to return to this page and add it here using the "I KNOW THE ANSWER!" button above. It's that easy to earn points!-

The ice maker on my upright freezer is not producing ice or not enough ice

...'s design and main function is produced, see "Using the control" below . Do not force the wire shutoff arm up or down ) position. Is the water line shutoff valve to the Off (arm up ) position and listen for ice maker to keep the freezer at or near 0°F (-17.8°C) under normal operating conditions. If... -

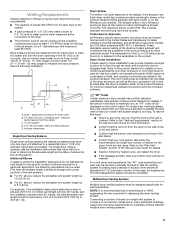

Wrinkles in load after Steam cycle - Steam dryer

... cotton, cotton-polyester blend, common knits and synthetic garments. Steam dryer Steam nozzle has blue-green discoloration - The Quick Refresh Steam cycle is connected to four dry items of the cycle? Unable to the water supply line? Did the garments contain starch? Dryer Load damp after Steam cycle - Results may yield better results than those without. Were... -

My dryer makes sounds or vibrations

..., 130 KB) Is the load knotted or balled up . Laundry items with a towel load inside the dryer along the front and rear edges of the drum. Remove any bunching that is a normal operation sound. Play the sound of the gas valve turning on is not level. Check if any missing...

Similar Questions

Can I Run The Steam Cycle Without Connecting The Water Line And Not Damage It.

I have hard water in my area and I don't want to connect the water line. Can I run the steam cycle w...

I have hard water in my area and I don't want to connect the water line. Can I run the steam cycle w...

(Posted by dsalour 8 years ago)

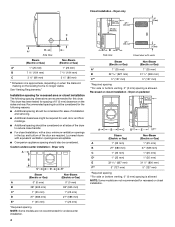

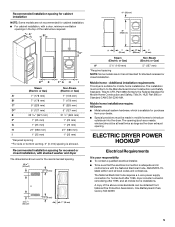

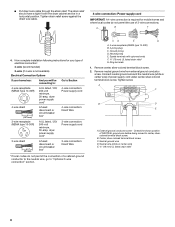

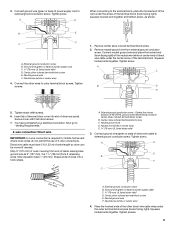

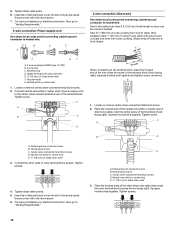

How Do I Connect Water Line For A Whirlpool Steam Dryer

(Posted by gfMe 9 years ago)

Is A Water Line Connected To A Steam Dryer Work

(Posted by eapkGthigh 9 years ago)

How Do You Make The Dryer Steam Function Work?

(Posted by Anonymous-51538 12 years ago)