Stihl MS 251 Support Question

Find answers below for this question about Stihl MS 251.Need a Stihl MS 251 manual? We have 1 online manual for this item!

Question posted by Jeffreyridd on January 27th, 2017

Stihl Ms251 Bar Oil

Current Answers

Answer #1: Posted by BusterDoogen on January 27th, 2017 9:21 AM

I hope this is helpful to you!

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful. Please feel free to submit further info for your question, if a solution was not provided. I appreciate the opportunity to serve you!

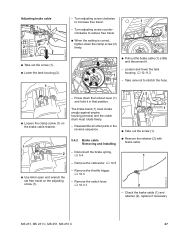

Related Stihl MS 251 Manual Pages

Similar Questions

Where is the chain bar oiler adjustment on the ms 251C? A supporting image may be helpful...

Is the amount of oil that lubricates the chain/bar on the MS 251 Easy Start adjustable? If so, where...

I want to increase the flow of oil to the chain of my stihl ms 251

Where is the adjustment for the bar oil, the adjusting screw that regulates the amount of oil on the...