Ryobi TS1342L Support Question

Find answers below for this question about Ryobi TS1342L.Need a Ryobi TS1342L manual? We have 4 online manuals for this item!

Question posted by usabus1107 on March 25th, 2013

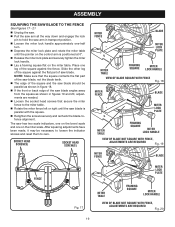

What Would Make The Plastic Guard Fall Apart Into Dozens Of Pieces?

The person who posted this question about this Ryobi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Ryobi TS1342L Manual Pages

Similar Questions

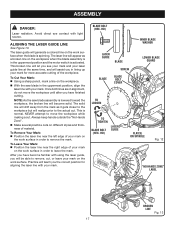

Light Won't Work How To Fix It

how to fix laser light so that it will come o

how to fix laser light so that it will come o

(Posted by island2discover 8 months ago)

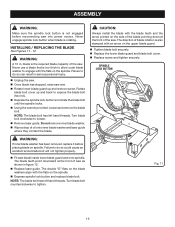

How Do I Replace The Lower Guard Of A 10' Compound Miter Saw(ts1342l)

(Posted by mvegab 8 years ago)

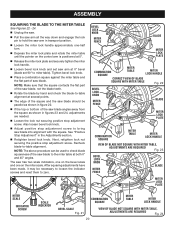

Cam Washer (plastic) Piece Behind Bevel Lock Lever Broke.

Literally just unboxed this rts20 set it up. Went to move the blade to (0) Degree and Cam washer (pl...

Literally just unboxed this rts20 set it up. Went to move the blade to (0) Degree and Cam washer (pl...

(Posted by Jlughart 12 years ago)

Lower Blade Guard Ts1342l Miter Saw

How do I replace the spring on my TS1342L 10" lower blade guard?

How do I replace the spring on my TS1342L 10" lower blade guard?

(Posted by MRELVIS 12 years ago)

Saw Guard Replacement

hOW DO I rellace the spring etc. on my lower blade guard?

hOW DO I rellace the spring etc. on my lower blade guard?

(Posted by MRELVIS 12 years ago)