Ryobi P320 Support Question

Find answers below for this question about Ryobi P320.Need a Ryobi P320 manual? We have 2 online manuals for this item!

Question posted by Christophertruelove on May 23rd, 2016

Hello. My Ryobi Nail Gun Won't Drive The Pins Home. Tried Everything. Can You He

the noise coming from the gun is quieter compared to when I first started using it. I've only used it for about an hour. Cheers

Current Answers

Answer #1: Posted by Odin on May 23rd, 2016 7:02 AM

See this manual page: http://bit.ly/1WcDpiD. The second-listed PROBLEM is yours. Listed are 3 possible causes and solutions.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

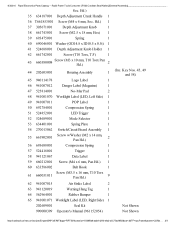

Related Ryobi P320 Manual Pages

Similar Questions

Broken Part On A Air Strike Nail Gun

a cannot find the part number..its the part where the (no-mark )rubber pushes on .the part where you...

a cannot find the part number..its the part where the (no-mark )rubber pushes on .the part where you...

(Posted by frankunwin2356 1 year ago)

Model 300 Nail Gun Is Disassembled. How Can The Compression Spring Be Relaxed To

how is the spring relaxed to allow reassembly

how is the spring relaxed to allow reassembly

(Posted by Dgreen85 2 years ago)

Royobi Cordless Nail

ryobi cordless nail gun won't fire an light blinks

ryobi cordless nail gun won't fire an light blinks

(Posted by augustp 8 years ago)

Trouble Nailing

I have the ryobi airstrike nail gun. When i go to shot a nail it sends 2-3 nails at a time. Wanting ...

I have the ryobi airstrike nail gun. When i go to shot a nail it sends 2-3 nails at a time. Wanting ...

(Posted by mconn625 8 years ago)

Won't Fire

My "airstrike" nail gun was working great, now nothing. There is nothing stuck. I've tried changing ...

My "airstrike" nail gun was working great, now nothing. There is nothing stuck. I've tried changing ...

(Posted by Jenkseric 10 years ago)