Ryobi P320 Support Question

Find answers below for this question about Ryobi P320.Need a Ryobi P320 manual? We have 2 online manuals for this item!

Question posted by 4jannburgs on February 23rd, 2015

Not Enough Penetration.

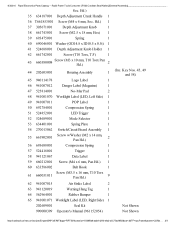

How to replace drive assembly? Drive plate wornout

Current Answers

Related Ryobi P320 Manual Pages

Similar Questions

Magazine Support Failure On Ryobi P320 Brad Nailer Airstrike

my magazine support shot off of my Ryobi brad nailer when trying to load why did this happen

my magazine support shot off of my Ryobi brad nailer when trying to load why did this happen

(Posted by Ianlowe76 3 years ago)

Are Plastic Or Stainless Steel Brads Available For Ryobi P320?

Im making model boat hulls for kids to complete, and need either stainless or plastic brads to assem...

Im making model boat hulls for kids to complete, and need either stainless or plastic brads to assem...

(Posted by robert21894 5 years ago)

Ryobi Bt 3000 Table Saw Drive Belts Serial 000580 (about 20/25 Yrs Old)

I am having difficulty obtaining the correct drive belts for the above machine. the last belts I bou...

I am having difficulty obtaining the correct drive belts for the above machine. the last belts I bou...

(Posted by fredmurrell 6 years ago)

My P320 Just Flashes When I Put A Battery In

my p320 just flash when you put a fully charged battery in

my p320 just flash when you put a fully charged battery in

(Posted by nolimitsbob 8 years ago)

Drive Piston Placement

How does the drive piston get assembled insie the gear

How does the drive piston get assembled insie the gear

(Posted by monicacmurray 10 years ago)