Ridgid R4331 Support Question

Find answers below for this question about Ridgid R4331.Need a Ridgid R4331 manual? We have 1 online manual for this item!

Question posted by Kenandjae on January 6th, 2016

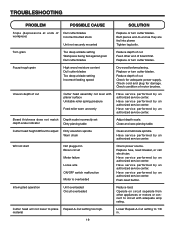

Rigid R4331 Planer Won't Run

Current Answers

Answer #2: Posted by helpowlsupport on January 7th, 2016 2:53 AM

the most common cause for devices to stop functioning is when the fuse is blown, you can get your device's fuse at any electrical repair store, it costs less than a dollar if you know what exactly is supposed to be done. the following are a few maintenance tips for the device

- Regularly wax bed

- Change blades

- Apply paste wax to shaving passage

please support my effort of research by accepting the solution to your question . It will be very kind and helpful of you to do so. For more accurate information please submit more details here and I will get

right back to you.

thankyou for asking!

"@ your service, [email protected] "

Related Ridgid R4331 Manual Pages

Similar Questions

I've had my r4331 planer for under a month and it seems to be more or less rubbing instead of cuttin...

Boards jump and don't feed without pulling them through unit, replaced blades cuts good, but same is...

Rigid hammer drill. My chuck's teeth are stuck and need a route to get it fixed.

Moter runs very slow and has no power & does not speed up ms255sr . Is there any fuse or relay d...