Ridgid OL50145MWD Support Question

Find answers below for this question about Ridgid OL50145MWD.Need a Ridgid OL50145MWD manual? We have 1 online manual for this item!

Question posted by Davewendytcc on December 29th, 2013

Compressor Cuts Out

Compressor runs for 10 or 15 sec then cuts out. If you push reset it will again work for a short while????

Current Answers

There are currently no answers that have been posted for this question.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Related Ridgid OL50145MWD Manual Pages

Operation Manual - Page 1

... ACIETE -

WARNING:

To reduce the risk of operation, and operator safety. TAN

4

2

50

100 150

0

0 psi

200

bar 230

K - OPERATOR'S MANUAL

5 Gallon portable Air Compressor

OIL LUBRICATED OL50145MW

5

Ga1l8l,o81nL8i,t7reLitro 4.4

0S,1C2F0mM,312/M@m3in/9M@0inP62@S1I6k,P12a14b5arM9a9x9

PSI KpA 9,99

bar

ON

OFF I

O

MINOIIWL LHUEBEELPBUAMRPR-OPOWMPEC1AOHUMLEP- SAVE THIS...

Operation Manual - Page 2

... disclaims any liabilities whatsoever for any loss, personal injury, or damage.

DANGER:

This compressor/pump is intended or implied. RIDGID® and One World Technologies, Inc. TABLE OF ... Glossary of Terms...8 Features...9 Assembly...10-11 Operation...12-14 Maintenance...15-16 Troubleshooting...17 Warranty...18 Customer...

Operation Manual - Page 3

...pressure regulator knob fully clockwise

after shutting off compressor. Do not use and reduce the risk of electric shock. Maintain tools with grounded surfaces such as in unexpected situations.... against flying fasteners and debris, which may result

sense when operating a power tool. For example, the working area may

from heat, oil, sharp edges, or moving parts.

...

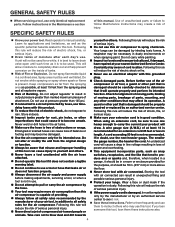

Operation Manual - Page 4

... of Bursting. Do not carry while painting. Inspect tool cords and hoses periodically and, if damaged, have repaired at least 15 feet from the spraying area and all safety rules for the ... air hose attached.

Do not operate this air compressor to all explosive vapors.

Risk of your power tool. Do not alter or modify the unit from the spraying area as...

Operation Manual - Page 5

...the risk of Fire or Explosion

Do not expose to rain or use at least 15 feet from the air compressor should never be grounded.

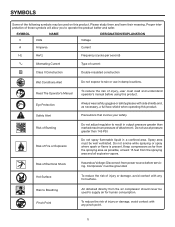

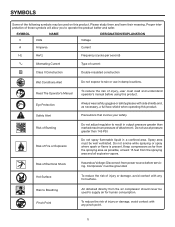

Please study them and learn their meaning.

Always wear ...before using this product. Do not smoke while spraying or spray where spark or flame is present. Compressor must be well ventilated. Do not use in a confined area.

Spray area must be used ...

Operation Manual - Page 6

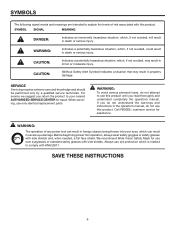

...a potentially hazardous situation, which is marked to explain the levels of any power tool can result in property damage. SERVICE

Servicing requires extreme care and knowledge and should .... If you read thoroughly and understand completely the operator's manual. Before beginning power tool operation, always wear safety goggles or safety glasses with side shields.

CAUTION:

(Without...

Operation Manual - Page 7

... current to result in figure 1. A line intended only for use . Position the cord so that is green with a power tool. Failure to determine the minimum wire size required in a loss of the working with or without yellow stripes is equipped with lower voltage. Repair or replace a damaged or worn cord immediately.

An...

Operation Manual - Page 8

... Tank

Cylindrical component which the motor will not automatically start and control the compressor unless the manual On/Off Switch is reached and starts the compressor when the air pressure drops below the cut -off the compressor if the temperature of the compressor. Cut-In Pressure

The low pressure at the outlet by the force of...

Operation Manual - Page 9

...

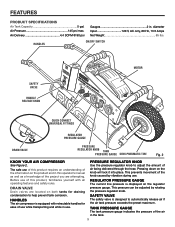

- SORTIE

MOTOR

ON OFF

regulator pressure gauge

DRAIN VALVE

pressure regulator knob tank

pressure gauge sEMI-PNEUMATIC TIRE

Fig. 2

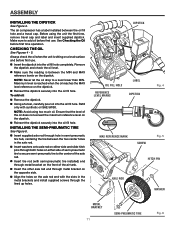

KNOW YOUR air compressor

See Figure 2. HANDLEs

The air compressor is equipped with all operating features and safety rules. REGULATOR PRESSURE GAUGE

The current line pressure is designed to automatically release air if...

Operation Manual - Page 10

... operated the product. If any parts are replaced.

SORTIE

10

TANK

4

6

80 2 40

120

0

bar

160

Fig. 3... handle release knob and sliding handle through slot.

Push handle all items listed in the packing list are included....in a hazardous condition leading to heed this product. PACKING LIST

Air Compressor Handles (2) Phillips Head Screw (4) Wheel Axle Rod Hitch Pins (2)...

Operation Manual - Page 11

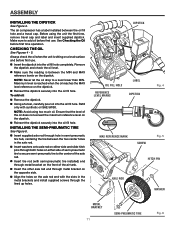

... time,

remove travel cap. SCREW

Fig. 5

HITCH PIN

Align the holes on the axle rod end with synthetic oil SAE 5W50. dipstick

The air compressor has a label installed between the MIN and MAX reference levels on a level surface and before first time operation. n Insert the dipstick into the oil fill...

Operation Manual - Page 12

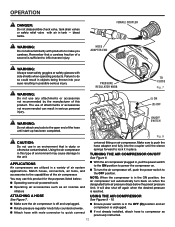

...serious personal injury. The use any tools to lock it in the ON position, the air compressor will also shut off

ON/OFF ...air system applications. tURNING THE AIR COMPRESSOR On/OFF

See Figure 8.

using the air compressor

See Figures 9 - 10. n If not already installed, ...not recommended by the manufacturer of the air compressor. Make sure to push the hose adapter end fully into your eyes...

Operation Manual - Page 13

...of in the air tool manual, you intend to release until tightly closed.

13

To drain:

n Turn the air compressor off. n Release ...personal injury. Check the tool manual to avoid damage to use . PRESSURE REGULATOR KNOB

Fig. 10

n Control the amount ...the air compressor and release all air pressure, remove and clean valves, then reinstall. OPERATION

n Attach 1/4 in and/or running unattended....

Operation Manual - Page 14

... should be allowed to tamper with the safety valve. Failure to fill. Air must be checked before manual resetting. n Unplug the air compressor for 30 minutes before each day of the air compressor. n Turn the air compressor on.

14 Anything loosened from this condition could result in death or serious personal injury.

n Turn the...

Operation Manual - Page 15

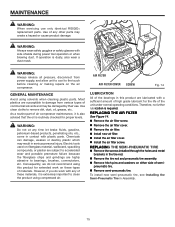

... their use only identical RIDGID® replacement parts. pneumatic tire. Remove semi-pneumatic tire.

Electric tools used on either side of air compressor maintenance, it is routinely checked for extended work with side shields during power tool operation or when blowing dust.

Use of any of materials. GENERAL MAINTENANCE

Avoid using this product...

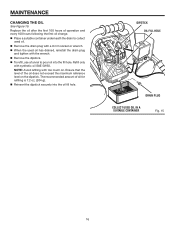

Operation Manual - Page 16

... 5W50. DIPSTICK oil fill hole

ON

OFF I

O

ON

drain plug

COLLECT USED OIL IN A SUITABLE CONTAINER

Fig. 15

16 n Reinsert the dipstick securely into the fill hole. Replace the oil after the first 100 hours of oil for... first oil change. MAINTENANCE

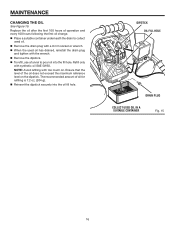

CHANGING THE OIL

See Figure 15. Ensure that the level of the oil does not exceed the maximum reference level on the dipstick.

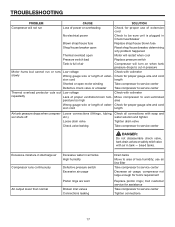

Operation Manual - Page 17

... for proper gauge wire and cord

sion cord

length

Shorted or open

Motor will restart when cool

Pressure switch bad

Replace pressure switch

Tank is full of air

Compressor will turn on when tank pressure drops to cut-in tank - Check for assistance Take compressor to service center

danger:

Do not disassemble check valve...

Operation Manual - Page 18

... by calling (toll free) 1-800-4-RIDGID or by the limited warranty for the balance of this RIDGID® Air Compressor, you . freight prepaid, or take it ;

Consumable accessories provided with the tool such as, but not limited to you may not be transferred. ADDITIONAL LIMITATIONS

To the extent permitted by applicable law...

Similar Questions

Saw Blade Stops On Cut

why does mitter saw blade stop in the middle of the cut

why does mitter saw blade stop in the middle of the cut

(Posted by amazingwoodflooring 8 years ago)

How To Repai The Rails For Cutting Table On A 10' Ridgid Tile Saw Model# R4010

(Posted by MOTODAD 10 years ago)

Tristack Compressor Repair

fills up to only 50 psi. it will keep running but not gain anymore pressure.cant detect any leaks in...

fills up to only 50 psi. it will keep running but not gain anymore pressure.cant detect any leaks in...

(Posted by bryanh222 10 years ago)

Ridged Gp80145sw Compressor

Cannot find the muffler for this compressor.

Cannot find the muffler for this compressor.

(Posted by benc07717 10 years ago)