Pfaff hobbylock 786 Support Question

Find answers below for this question about Pfaff hobbylock 786.Need a Pfaff hobbylock 786 manual? We have 1 online manual for this item!

Question posted by pgp37615 on July 1st, 2021

Why Does My Serger Seize Up When Sitting Idol For Few Months

Current Answers

Answer #1: Posted by SonuKumar on July 4th, 2021 2:23 AM

https://www.youtube.com/watch?v=Eha25W77BP4

https://www.youtube.com/watch?v=YJmTbAb8-YU

https://www.youtube.com/watch?v=2CXhlZn2DFM

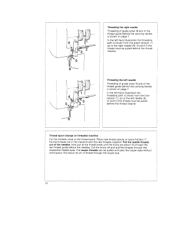

Why is my serger stuck?

Try disengaging the knife and running it. If it still jams something is probably wrong in the threading. If it runs ok make sure the knife is back in the right spot. It's really easy to put the knife back in place and think it's right and it's just a tiny bit off and everything goes wrong

Who makes Hobbylock Sergers?

Pfaff Hobbylock

The Pfaff Hobbylock 2.5 Serger is sturdy and easy to use. No need to worry about thread tension. The Hobbylock overlock machine has an Automatic Tension Dial, which sets the thread tension when selecting any of the 15 stitches - just start sewing.

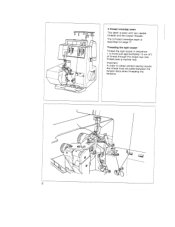

Why does my serger keep Unthreading?

If the tension on the top thread is too high or low the machine can often keep unthreading. Make sure the thread has the correct tension and if your stitches are loose you should probably try to tighten the thread a bit. ... If you are using a wrong size spool the thread might jump out of the needle continuously.

How do you service a serger?

Serger Maintenance

Gather a few tools to help the process go quickly and smoothly. ...

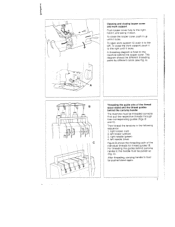

For deep cleaning, unthread the machine and remove the presser foot and needles. ...

Using a soft brush, such as a paint brush, lint brush or make-up brush, clean the lower area of the serger. ...

Use a pipe cleaner for hard-to-reach areas.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Answer #2: Posted by INIMITABLE on July 1st, 2021 4:34 PM

I hope this is helpful? PLEASE "ACCEPT" and mark it "HELPFUL" to complement my little effort. Hope to bring you more detailed answers

-INIMITABLE

Related Pfaff hobbylock 786 Manual Pages

Similar Questions

Needle holder clamp won't stay in place (rotates) tiny holes each side have no set screws. The two o...

Haven't used the machine in more than 10 years and it's stiff. How do I get it oiled and lubricated ...

Can I correct myself?

Hello, my Pfaff 786 Hobbylock serger suddenly started running slow. I have not changed any presets o...

I am cleaning the machine as recommended in the manual. How do I remove the "lower feed dog"? How d...