Husqvarna 359 Support Question

Find answers below for this question about Husqvarna 359.Need a Husqvarna 359 manual? We have 2 online manuals for this item!

Question posted by hayman17 on December 2nd, 2014

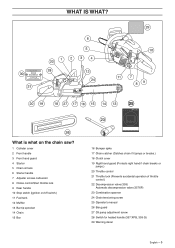

359 Oiler

I 'have a 359 that is not getting enough oil on the bar. I have taken all componets apart and cleaned and inspected them and reassembled. The holes in the bar are clean. Can an oil pump just wear out and still work but just not put out enough oil?

Current Answers

Answer #2: Posted by sabrie on December 10th, 2014 8:52 AM

The video on the link below will show you how to adjust the oil output

www.techboss.co.za

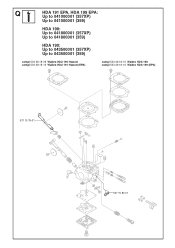

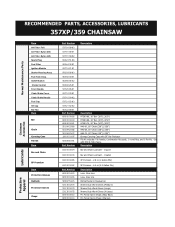

Related Husqvarna 359 Manual Pages

Similar Questions

Does The Husqvarna 435 Have An Oiler Adjustment Screw

(Posted by tedmccormick65 1 year ago)

Needle Bearing Maintenance.

How do I get to the needle bearing to grease it ? I can see no way to remove the clutch assembly in ...

How do I get to the needle bearing to grease it ? I can see no way to remove the clutch assembly in ...

(Posted by jerryjordan0 1 year ago)

359 Carb Problems .

i keep seeing carb recalls for 359 models and i have one that started out the best saw i owned and t...

i keep seeing carb recalls for 359 models and i have one that started out the best saw i owned and t...

(Posted by brookins69phillip 5 years ago)