Husqvarna 359 Support Question

Find answers below for this question about Husqvarna 359.Need a Husqvarna 359 manual? We have 2 online manuals for this item!

Question posted by jerryjordan0 on July 6th, 2022

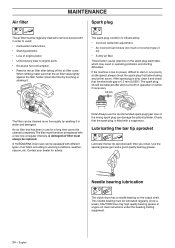

Needle Bearing Maintenance.

Current Answers

Answer #1: Posted by SonuKumar on July 7th, 2022 7:19 AM

https://www.youtube.com/watch?v=YM07wKXX06Q

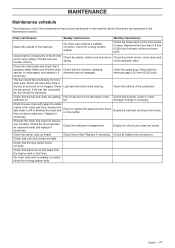

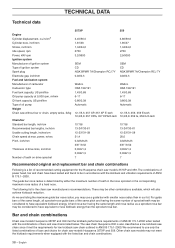

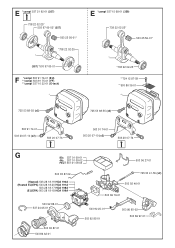

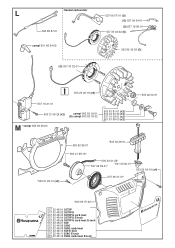

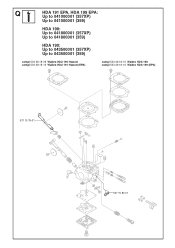

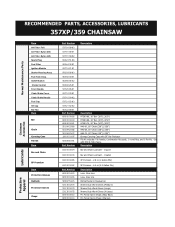

https://www.manualslib.com/manual/495549/Husqvarna-359-35279.html?page=31

https://www.manualslib.com/manual/667186/Husqvarna-357xp.html?page=33

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Husqvarna 359 Manual Pages

Similar Questions

i keep seeing carb recalls for 359 models and i have one that started out the best saw i owned and t...

It just started this year. While the blades are engaged and the engine throttle is fast, the engine ...

I have a Husqvarna YTH 2042. Went out to start the mower and battery didn't have enough power in it ...

I 'have a 359 that is not getting enough oil on the bar. I have taken all componets apart and cleane...