Hayward EcoStar Support Question

Find answers below for this question about Hayward EcoStar.Need a Hayward EcoStar manual? We have 3 online manuals for this item!

Question posted by rmbunz2 on December 2nd, 2011

Motor Drive Burned Up, Warranty?

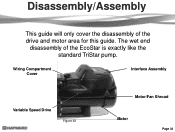

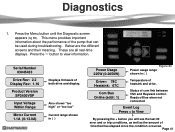

Purchased EcoStar IS3400VSP pump June 2011. Been running for 5 months on local pump program. Changed program today for slower speeds. Hooked up external relay speed control wiring and burnedup the Motor Drive. Still don't know why the motor drive burned up. Can't find any problem with the external relay speed control wiring?

Warranty ? or what are my options for repair or replacement?

Current Answers

Related Hayward EcoStar Manual Pages

Similar Questions

How To Fix Ecostar Comm Bus Offline & Pro Logic Vsp Comm Error?

I cannot get my Hayward Pro Logic board to communicate with my Hayward Ecostar VSP pump. The pump sa...

I cannot get my Hayward Pro Logic board to communicate with my Hayward Ecostar VSP pump. The pump sa...

(Posted by m72422 6 years ago)

Hayworc Ecostar Pump.'keypad Failed' Erroer Message

Pump display shows this message. Keypad failed. Hayword ecostar is3400vsp pump.

Pump display shows this message. Keypad failed. Hayword ecostar is3400vsp pump.

(Posted by Harenhema 9 years ago)

Deactivate Timer

I have a new ecostar pump. I don't want to use theEcostar timer as my pool heater is set to switch o...

I have a new ecostar pump. I don't want to use theEcostar timer as my pool heater is set to switch o...

(Posted by ffodemes 10 years ago)

We Want To Purchase A Heat Pump But Need To Know What Size You Recommend

We live in Central Pennsylvania and our pool is 16x32 inground with the deep end being 6'. What size...

We live in Central Pennsylvania and our pool is 16x32 inground with the deep end being 6'. What size...

(Posted by democat1 11 years ago)

Dual Pool Spa System But The Settings Menu Doesn't Show Pool Heater Only Spa Hea

(Posted by Anonymous-39619 12 years ago)