Craftsman 21239 Support Question

Find answers below for this question about Craftsman 21239 - 12 in. Sliding Compound Miter Saw.Need a Craftsman 21239 manual? We have 1 online manual for this item!

Question posted by Susandizzine on February 4th, 2013

Saw Will Not Cut Straight

Brought back to sears can not find the problem

Current Answers

Related Craftsman 21239 Manual Pages

Similar Questions

How To Replace A Broken Spring Of 71/4' Craftsman Slide Compound Miter Saw. Mode

I've a spring broken of 71/4" craftsman slide compound miter saw. Model 137.211940. Please tell me h...

I've a spring broken of 71/4" craftsman slide compound miter saw. Model 137.211940. Please tell me h...

(Posted by ccc692 8 years ago)

Why Is My Brand New Craftsman Saber Saw Unable To Cut A Straight Line.it Also Cu

(Posted by csullivan2 10 years ago)

How Do I Unlock The Saw Stuck In The Upright Position

(Posted by jamieleighton 10 years ago)

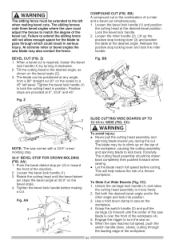

Straught Cut

I am having trouble getting the blade adjusted to cut straight

I am having trouble getting the blade adjusted to cut straight

(Posted by rossand 11 years ago)

Saw Blade Not Centered

i just bought the floor model 12-in Sliding compound miter saw with laser trace M# 137.212390. In...

i just bought the floor model 12-in Sliding compound miter saw with laser trace M# 137.212390. In...

(Posted by randys113 12 years ago)