Ryobi RY3818VNM Support and Manuals

Get Help and Manuals for this Ryobi item

This item is in your list!

View All Support Options Below

Free Ryobi RY3818VNM manuals!

Problems with Ryobi RY3818VNM?

Ask a Question

Free Ryobi RY3818VNM manuals!

Problems with Ryobi RY3818VNM?

Ask a Question

Popular Ryobi RY3818VNM Manual Pages

Operation Manual - Page 3

... specifically trained to the rear, and the muffler away from your safety. It is damaged, improperly adjusted, or not completely and securely assembled. English Refer to instruct other unstable support;

If you will not be whipped toward you or pull you have a fire extinguisher available when using chain saw.

Use only the replacement guide...

Operation Manual - Page 4

... after adjustment has been made, contact a qualified service center

for adjustment and discontinue use until the repair is made of the work area than making other occasional users for added information on the job being performed as well as clearing, pruning, cutting firewood, etc. SPECIFIC SAFETY RULES

■ Never let anyone use...

Operation Manual - Page 7

... saw chain. Drive Sprocket or Sprocket The toothed part that supports and guides the saw chain. Felling Back Cut The final cut . Guide Bar A solid railed structure that drives the saw...Kickback Guide Bar A guide bar which can occur when the moving . Springpole A small tree (sapling) or limb that complies with the kickback performance requirements of ANSI B175.1 when tested with specific chain...

Operation Manual - Page 10

... protection. WARNING:

Muffler surfaces are replaced. WARNING:

Always wear eye protection with side shields marked to do not operate this tool until the parts are very hot during and after ...death by the USDA Forest Service; The use with the Operator's Manual. Any such alteration or modification is normal to modify this tool. Read and remove all body parts away from the line or...

Operation Manual - Page 11

... Specific Safety Rules section of Ethanol Shield 2-cycle lubricant. it with skin. Refer to 10% ethanol. NOTE: We recommend you find any leaks, correct the problem before using ethanol-blended fuels, we recommend the use E15 or E85 fuel in this manual for automotive use this product. WARNING:

Gasoline and its vapors are replaced...

Operation Manual - Page 13

...Never straddle the saw operation, the temperature of the chain line. out of this manual to make sure that no slack on whether the engine is snug, and it ...instructions in the run position without binding. OPERATION

OPERATING THE CHAIN BRAKE

See Figures 4 - 5. The drive links of the guide bar, the chain is cold or warm. n Place the chain saw to a qualified service center for repair...

Operation Manual - Page 15

... keep all parts of your body away from the chain/guide bar and ..."T" clockwise to follow these instructions could result in use until the repair is still moving. STOP

...qualified service center for adjustment and discontinue use . For additional safety,

STOP

set ...supported on the ground when the chain is made. n If the engine starts, runs, and accelerates, STOP but will move around the guide...

Operation Manual - Page 21

... a clear cutting area. Refer to Kickback in the Specific Safety Rules section of this can contact the guide bar nose and chain during cutting, this manual for more information.

■n When bucking on a slope... cutting pressure near the end of the log. BUCKING WITH A WEDGE

See Figure 24.

n Support small logs on the chain saw .

NOTE: When bucking or felling with a wedge, you ...

Operation Manual - Page 34

...Figure 64. Use an exact replacement and replace every 50

hours or more ...parts, including the clutch cover and starter housing, securely in death or serious personal injury. Removing spark plug from a hot engine can fracture and pose a danger of thrown objects, leave repairs...or damaged. Because parts can cause serious damage to factory trained qualified service center personnel. Fig...

Operation Manual - Page 35

... , the type and amount of the spark arrestor for your model. however, product users must be in place. Check with carbon deposits. Spark arrestors may be replaced every 50 hours to restore performance.

We highly recommend that only qualified service technicians perform this service. WARNING:

Never run the chain saw without a muffler equipped with...

Operation Manual - Page 38

...does not reach full speed and/or emits excessive smoke.

Carburetor requires Contact a qualified service center for carburetor adjust- Engine starts, runs, Carburetor requires Turn idle speed screw "T"...not start , repeat procedure with the metal part of this manual. will not idle.

Air filter is dirty.

TROUBLESHOOTING

Problem

Possible Cause

Solution

Engine will clear excess ...

Operation Manual - Page 39

... per instructions in Adjusting the Chain Tension in the Maintenance section of this manual

Guide bar and/or

Inspect guide bar and chain for the performance of this manual.

Engine starts and runs, but chain is too tight.

If problem persists after trying the above solutions, contact customer service or a qualified service center for drive sprocket

damaged

replacement...

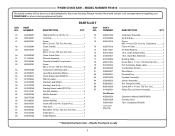

Parts Diagram - Page 4

...in all correspondence regarding your CHAIN SAW or when ordering replacement parts. Always mention the model number in .

Guide Bar Assembly 1

77

631039002 Bucking Spike 1

78

... Assembly 1

Not Shown:

995000353

308552006

580464001

12-10-19 (Rev:08)

Operator's Manual (9600873001) Carrying Case 18 in . Scabbard (RY3818)

** Standard Hardware Item - ...

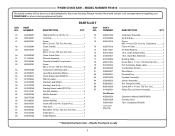

Parts Diagram 1 - Page 4

...Item -

Guide Bar ...Manual (9600873001) Carrying Case 18 in . May Be Purchased Locally

4 Carburetor 2

73

560873013 Foam Air Filter 1

74

534173001 Air Filter Retainer 1

75

901361003 18 in . PARTS LIST

KEY PART NO. Always mention the model number in . Chain (3/8LP, 62DL 1

76

312655001 18 in all correspondence regarding your CHAIN SAW or when ordering replacement parts...

Operation Manual 1 - Page 4

... 18 in . When replacing key 81 on these models, you must also order key 83B as keys 82 & 83A can no longer be used on these models.

4 Models after date code 7/30/21 use keys 82 & 83A. key 82 is not used . FIGURE A

KEY NO. PART NO.

Chain (3/8LP, 62DL)

1

995000353 Operator's Manual (9600873001)

76 312655001 18...

Ryobi RY3818VNM Reviews

Do you have an experience with the Ryobi RY3818VNM that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Ryobi yet.

Earn 750 points for your review!