Craftsman 21609 - 18 in. Scroll Saw Support and Manuals

Get Help and Manuals for this Craftsman item

View All Support Options Below

Free Craftsman 21609 manuals!

Problems with Craftsman 21609?

Ask a Question

Free Craftsman 21609 manuals!

Problems with Craftsman 21609?

Ask a Question

Most Recent Craftsman 21609 Questions

Motor Carbon Brushes

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

Hello....I'm looking for substitute parts, the original are not longer available.It's for a Craftsma...

(Posted by jriofrio 10 months ago)

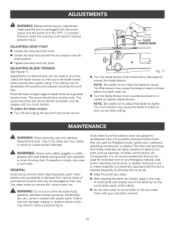

It Is Getting Power. The Light Works But The Saw Will Not Operate.

(Posted by Anonymous-123838 10 years ago)

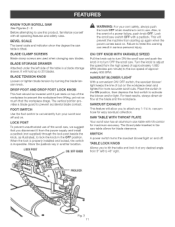

Can't Tighten Blades There Is No Tension

Blade tensioner doesn't have any tension. I tey tightening the balde and it won't tighten. Please he...

Blade tensioner doesn't have any tension. I tey tightening the balde and it won't tighten. Please he...

(Posted by jcvw57 10 years ago)

Power And Control Cards.

I need the power and control cards for my saw, saw has not been used much. but cards need to be repl...

I need the power and control cards for my saw, saw has not been used much. but cards need to be repl...

(Posted by jimwjohnson1949 11 years ago)

Foot Switch Replacement

(Posted by Anonymous-57865 11 years ago)

Popular Craftsman 21609 Manual Pages

Craftsman 21609 Reviews

We have not received any reviews for Craftsman yet.