Singer One Support Question

Find answers below for this question about Singer One.Need a Singer One manual? We have 19 online manuals for this item!

Question posted by Kblakey11 on August 27th, 2016

C6 Error Continues. Re-threaded The Machine Multiple Times Ensuring The Thread W

have rethreaded the machine sooooo many times following the video to ensure the thread was "under the black thing" and "flossy" to ensure it was in place. I can only take about 6-7 stitches and BAM C6! Frustrated!!

Current Answers

Answer #1: Posted by sinclair5178 on November 13th, 2020 1:06 PM

The the same thing was happening to me. I threaded and rethreaded the bobbin and the spool thread to no avail. What finally worked is to very firmly swish the spool thread through the top tension sensor, back and forth a little, then thread as usual. It must not have really caught the spool thread before . This whole problem started when I changed the spool thread so hopefully this is the answer.

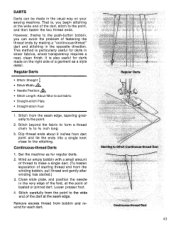

Related Singer One Manual Pages

Similar Questions

Why Won't My Machine Sew, Checked Bobbin And Retreaded. Has Power Just Will Not

the machine has power and threade correctly and bobbin is in right. It did freeze on me when sewing....

the machine has power and threade correctly and bobbin is in right. It did freeze on me when sewing....

(Posted by alewis41 7 years ago)

I'm Getting C6 Error Message In Singer One Plus.

The manual suggests that I have a broken top thread. I have retreaded several times and it lets me s...

The manual suggests that I have a broken top thread. I have retreaded several times and it lets me s...

(Posted by chockley 8 years ago)

We Are Getting A C6 Error On A Singer One. The Thread Seems To Be Threaded Ok.

(Posted by kfoley22 8 years ago)

As Reparo The C4 Error

As Reparo The C4 Error In My Machine Singer 6160 my machine makes a loud noise, I send a C4 mistak...

As Reparo The C4 Error In My Machine Singer 6160 my machine makes a loud noise, I send a C4 mistak...

(Posted by Anonymous-142756 9 years ago)

C6 Error

I keep getting a c6 error on my singer one machine. I lost my manual and I can't keep figure it out.

I keep getting a c6 error on my singer one machine. I lost my manual and I can't keep figure it out.

(Posted by Kpunderwood 9 years ago)