Ryobi TSS101L Support Question

Find answers below for this question about Ryobi TSS101L.Need a Ryobi TSS101L manual? We have 4 online manuals for this item!

Question posted by thguenand on October 13th, 2015

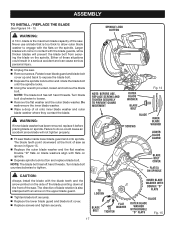

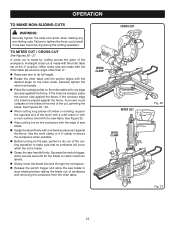

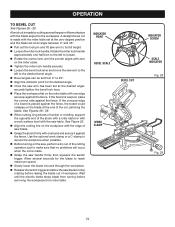

I Have To Remove Arm Support Bracket To Replace It After A Falling Accident

Current Answers

Answer #1: Posted by TommyKervz on October 14th, 2015 3:16 AM

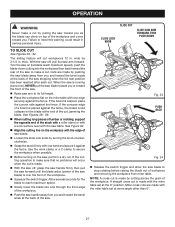

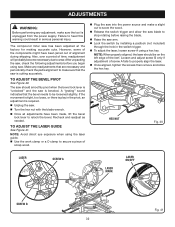

Click the link below to find your nearest authorised service and repair providers.

http://ryobi.com.au/servicecentrelocator.

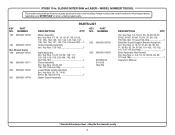

For part list and diagram please click here

Related Ryobi TSS101L Manual Pages

Similar Questions

dear sir, do you have fan " blade " for Ryobi p2105 leaf blower or replacement part, thank you.

Part #s for above: 089100121610 089100121112 Have apparently discontinued. Does anyone have a fix?

The support arm (part number 080009002037) on mine broke. It appears as though this part has been di...

I need a replacement battery for my Ryobi model HP41L. Can you provode or direct men to where to pur...

I recently bought the Ryobi mitre saw TSS101L used with no blade, turned it on seamed to work fine, ...