Ryobi RY34426 Support Question

Find answers below for this question about Ryobi RY34426.Need a Ryobi RY34426 manual? We have 5 online manuals for this item!

Question posted by battlemagemike on July 1st, 2014

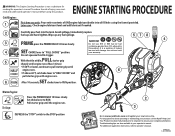

How To Replace The Throttle Trigger On Ry34426

took appart cant figure how to get back together. cant find any good pictures

Current Answers

Answer #1: Posted by harrytonia on July 1st, 2014 11:37 AM

Download repair sheet and replacement part list below

http://www.helpowl.com/manuals/Ryobi/RY34426/194259

http://www.helpowl.com/manuals/Ryobi/RY34426/194259

PLEASE ACCEPT IF SATISFIED

if you are not satisfied with my help please don't rate it but continue to ask another question. MAY THE MERCY OF GOD BE WITH YOU, YOUR FRIENDS AND FAMILY.

Related Ryobi RY34426 Manual Pages

Similar Questions

Throttle Trigger Assembly

how do I replace the throttle trigger assemby

how do I replace the throttle trigger assemby

(Posted by mavnjv 11 years ago)

Is This A Carburator Problem.

My string trimmer operates at half-speed only. No visible debris. Have to hold throttle trigger down...

My string trimmer operates at half-speed only. No visible debris. Have to hold throttle trigger down...

(Posted by lroquemore 11 years ago)

Ry28000 Throttle Assembly Replacement

I need a correct RY28000 throttle body diagram. Item #4 in RY28000 parts explosion diegram is not pr...

I need a correct RY28000 throttle body diagram. Item #4 in RY28000 parts explosion diegram is not pr...

(Posted by wescox1 11 years ago)